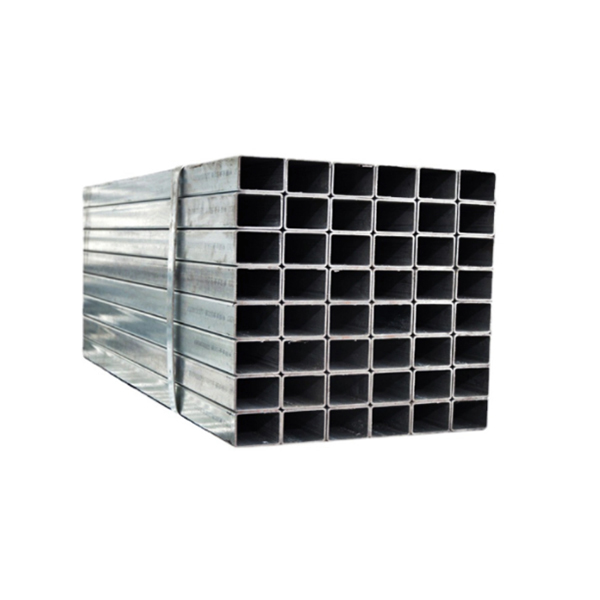

Wholesale Price Steel Hollow Section - Alloy Square Rectangular Tube – Zheyi

Wholesale Price Steel Hollow Section - Alloy Square Rectangular Tube – Zheyi Detail:

Alloy square rectangular tube Also known as square and rectangular cold formed hollow steel, referred to as square pipe and rectangular pipe, code F and J respectively

1. Alloy square rectangular tube The allowable deviation of wall thickness shall not exceed positive or negative 10% of the nominal wall thickness when the wall thickness is less than 10mm, and positive or negative 8% of the nominal wall thickness when the wall thickness is greater than 10mm, except for the wall thickness of the corner and weld zone.

2. Alloy square rectangular tube Usually the delivery length is 4000mm-12000mm, with 6000mm and 12000mm in the majority. Square rectangular tube allows delivery of not less than 2000mm short and irregular products, can also be delivered in the form of interface tube, but the customer should remove the interface tube when using. The weight of short and irregular length products shall not exceed 5% of the total delivery quantity, and for square rectangular tubes with theoretical weight greater than 20kg/m shall not exceed 10% of the total delivery quantity

3. Alloy square rectangular tube The bending must not be greater than 2mm per meter and the total bending must not be greater than 0.2% of the total length

4. Alloy square rectangular tube According to the production process: hot rolled seamless square tube, cold drawn seamless square tube, squeeze seamless square tube, welded square tube.

The welded square pipe is divided into

1, according to the process: arc welding square tube, resistance welding square tube (high frequency, low frequency), gas welding square tube, furnace welding square tube

2, according to the weld – straight seam welding square pipe, spiral welding square pipe.

Alloy Square Rectangular Tube The Material Classification

Square tube according to the material: plain carbon steel square tube, low alloy square tube.

1, general carbon steel is divided into: Q195, Q215, Q235, SS400, 20# steel, 45# steel and so on.

2, low alloy steel is divided into: Q345, 16Mn, Q390, ST52-3, etc.

Production Standard Classification

Square tube according to production standards: gb square tube, Japanese standard square tube, British system square tube, American standard square tube, European standard square tube, non-standard square tube.

Section Shape Classification

Square pipes are classified according to section shape:

1, simple section of square tube: square tube, rectangular square tube.

2, complex section square tube: flower shaped square tube, open square tube, corrugated square tube, shaped square tube.

Specification

|

Surface finish |

Characteristics & Application |

| NO.1 | Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

| NO.2D | Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mo bile parts, build ing materrials and pipings. |

| NO.2B | The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses. |

| NO.3 | Polished with abra sive belt of grit #100#120,have bet ter bright ness with dis con tin u ous coarse stria, used as in ner and ex ter nal or na ments for building, elec tri cal ap pli anc es and kitchen uten sils etc. |

| NO.4 | Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments, elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright an nealed and skin passed, the prod uct has ex cel lent bright ness and good re flex iv i ty like mirror, used for lectrical appliances, mirror, kitch en apparatus, or na ment ma te ri als etc. |

Pipe Grade Data Sheet

|

Alloy |

UNS |

Description |

|

304/304L |

S30400/S30403 |

Chromium-Nickel austenitic alloy used in commercial applications. |

|

304 |

S30400 |

Chromium-Nickel austenitic alloy used in commercial applications. |

|

304L |

S30403 |

Chromium-Nickel austenitic alloy used in commercial applications. |

|

304H |

S30409 |

Chromium-Nickel austenitic alloy used in commercial applications. |

|

316/316L |

S31600/S31603 |

Molybdenum-bearing austenitic stainless steel which is more resistant to general corrosion and pitting/crevice corrosion. |

|

316 |

S31600 |

Molybdenum-bearing austenitic stainless steel which is more resistant to general corrosion and pitting/crevice corrosion. |

|

316L |

S31603 |

Molybdenum-bearing austenitic stainless steel which is more resistant to general corrosion and pitting/crevice corrosion. |

|

316H |

S31609 |

Molybdenum-bearing austenitic stainless steel which is more resistant to general corrosion and pitting/crevice corrosion. |

|

309S |

S30908 |

Austenitic stainless steel typically used for elevated temperature applications. |

|

309H |

S30909 |

Austenitic stainless steel typically used for elevated temperature applications. |

|

310S |

S31008 |

Austenitic stainless steel typically used for elevated temperature applications. |

|

310H |

S31009 |

Austenitic stainless steel typically used for elevated temperature applications. |

|

317 |

S31700 |

Molybdenum-bearing austenitic stainless steels which are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels. |

|

317L |

S31703 |

Molybdenum-bearing austenitic stainless steels which are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels. |

|

317LMN |

S31726 |

Fully austenitic, nitrogen-bearing, high-molybdenum stainless steel for use in high-chloride environments. |

|

321 |

S32100 |

A stabilized stainless steel which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 °F. |

|

321H |

S32109 |

A stabilized stainless steel which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 °F. |

|

347 |

S34700 |

Stabilized stainless steel which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 °F. |

|

347H |

S34709 |

Stabilized stainless steel which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 °F. |

|

348 |

S34800 |

Stabilized stainless steel which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 °F. |

|

348H |

S34809 |

Stabilized stainless steel which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 °F. |

|

AL 611 |

S30601 |

Low-carbon, silicon containing, austenitic stainless steel typically used for applications in the chemical industry. |

Product Display

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for Wholesale Price Steel Hollow Section - Alloy Square Rectangular Tube – Zheyi , The product will supply to all over the world, such as: Ottawa, Boston, Japan, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.