Well-designed 3lpe Oil Pipeline Liquid Epoxy Anti Corrosion Plastic Coated Spiral Welded Steel Pipe

carry on to improve, to ensure merchandise quality in line with market and shopper standard prerequisites. Our firm has a high quality assurance program are actually established for Well-designed 3lpe Oil Pipeline Liquid Epoxy Anti Corrosion Plastic Coated Spiral Welded Steel Pipe, For additional queries or should you might have any question regarding our goods, make sure you do not hesitate to call us.

carry on to improve, to ensure merchandise quality in line with market and shopper standard prerequisites. Our firm has a high quality assurance program are actually established for China Liquid Epoxy Anti-Corrosion Pipe and Plastic Coated Anticorrosive Pipe, Custom orders are acceptable with different quality grade and customer’s especial design. We’ve been looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

Powder coated plastic steel tube, Also known as coated plastic pipe, steel-plastic composite pipe, coated plastic composite steel pipe, steel pipe as the matrix, through spraying, rolling, dipping, suction process in steel pipe (bottom pipe) inner surface of a layer of plastic anticorrosive layer or in the inner and outer surface of the plastic anticorrosive layer of steel-plastic composite steel pipe. Coated steel tube has excellent corrosion resistance and relatively small friction resistance. Epoxy resin coated plastic steel pipe is suitable for water supply and drainage, sea water, warm water, oil, gas and other media transportation, PVC coated plastic steel pipe is suitable for drainage, sea water, oil, gas and other media transportation.

Powder Coated Plastic Steel Tube, Technical Parameters

General colors: black, gray, blue, red, white, green;

Coating thickness: PE(modified polyethylene) coating thickness of 400um – 1000um, EP(epoxy resin) coating thickness of 100um-400um;

Coating method: PE(polyethylene) for hot dip EP, (epoxy resin) for internal and external spraying;

Product specifications: DN15 — DN1660;

Ambient temperature: -30℃ to 120℃;

Connection mode: screw buckle (DN15-DN100), groove (DN65-DN400), flange (applicable to any caliber), welding type, bimetal connection, socket, pipe joint, sealed connection, etc.

Powder Coated Plastic Steel Tube, Product Features

Powder coated plastic steel tube, Is the use of PE(modified polyethylene) hot-dip plastic or EP(epoxy resin) for internal and external coating products, with excellent corrosion resistance. At the same time, the coating itself also has good electrical insulation and will not produce electrical erosion. Low water absorption, high mechanical strength, small friction coefficient, can achieve the purpose of long-term use. It can also effectively prevent the destruction of plant roots and soil environmental stress. Convenient connection and easy maintenance.

Powder Coated Plastic Steel Tube, Product Advantages

1. Adapt to buried and humid environment, and can withstand high temperature and very low temperature.

2. Strong anti-interference ability. If coated plastic steel tube is used as cable sleeve, it can effectively shield external signal interference.

3. Good pressure strength, maximum pressure up to 6Mpa.

4. Good insulation performance, as a wire protection tube will never happen leakage phenomenon.

5. No burr, smooth pipe wall, suitable for the construction of wire or cable

Powder Coated Plastic Steel Tube, Application Field

1. Various forms of circulating water system (civil circulating water, industrial circulating water), excellent performance, anti-corrosion life up to 50 years.

2. Fire water supply system.

3. Water supply and drainage of each building (especially for cold and hot water systems of guesthouses, hotels and high-end residential areas).

4. All kinds of chemical fluid transport (acid, alkali, salt corrosion).

5. Buried pipe and crossing pipe of wire and cable.

6. Ventilation pipes, supply pipes and drainage pipes of mines and mines

Constituent Of The Material

| Grade | C | Mn | Si | S | P | UTS(MPa) | YS(MPa) | EI(%) |

| Q235B | 0.12-0.20 | 0.30-0.70 | 0.30 | 0.045 | 0.045 | 375-500 | 235 | 26 |

| Q345B | 0.12-0.20 | 1.20-1.60 | 0.20-0.55 | ≤0.045 | ≤0.045 | 510-600 | 345 | 22 |

| 20#(GB) | 0.17-0.23 | 0.38-0.65 | 0.17-0.37 | ≤0.030 | ≤0.030 | 410-550 | ≥245 | ≥20 |

| HDPE PIPE SIZES CHART | |||||||||||||||

| Dia | Deviation | 0.4Mpa | 0.5Mpa | 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6MPa | 2.0Mpa | ||||||

| Thickness | Thickness | Thickness | Thickness | Thickness | Thickness | Thickness | Thickness | ||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||||||

| 16 | 0.3 | 2.3 | |||||||||||||

| 20 | 0.3 | 2.3 | 2.3 | ||||||||||||

| 25 | 0.3 | 2.3 | 2.3 | 3 | |||||||||||

| 32 | 0.3 | 2.3 | 2.4 | 3 | 3.6 | ||||||||||

| 40 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.5 | |||||||||

| 50 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | ||||||||

| 63 | 0.4 | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | ||||||||

| 75 | 0.5 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | ||||||||

| 90 | 0.6 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | ||||||||

| 110 | 0.7 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | ||||||||

| 125 | 0.8 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | ||||||||

| 140 | 0.9 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | ||||||||

| 160 | 1 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | ||||||||

| 180 | 1.1 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | ||||||||

| 200 | 1.2 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | ||||||||

| 225 | 1.4 | 8.6 | 10.8 | 13.4 | 16.6 | 16.6 | 25.2 | ||||||||

| 250 | 1.5 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | ||||||||

| 280 | 1.7 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | ||||||||

| 315 | 1.9 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 | ||||||

| 355 | 2.2 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 | ||||||

| 400 | 2.4 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | ||||||

| 450 | 2.7 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | ||||||

| 500 | 3 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | ||||||

| 560 | 3.4 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | ||||||

| 630 | 3.8 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 | ||||||

| 710 | 6.4 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 | ||||||

| 800 | 7.2 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 | ||||||

| 900 | 8.1 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |||||||

| 1000 | 9 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |||||||

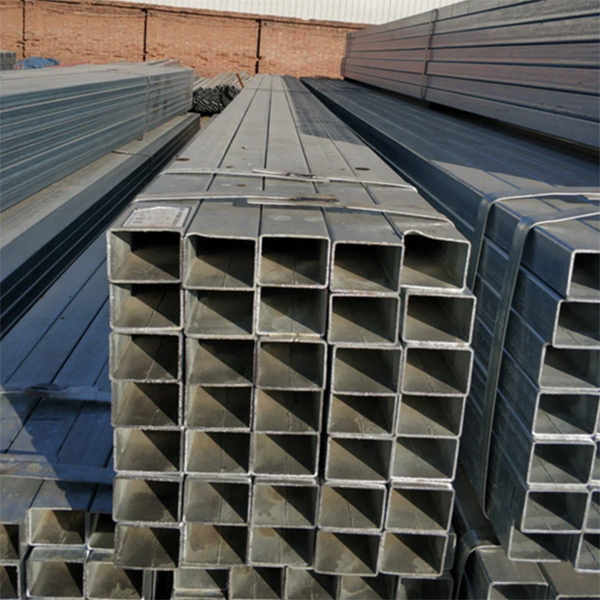

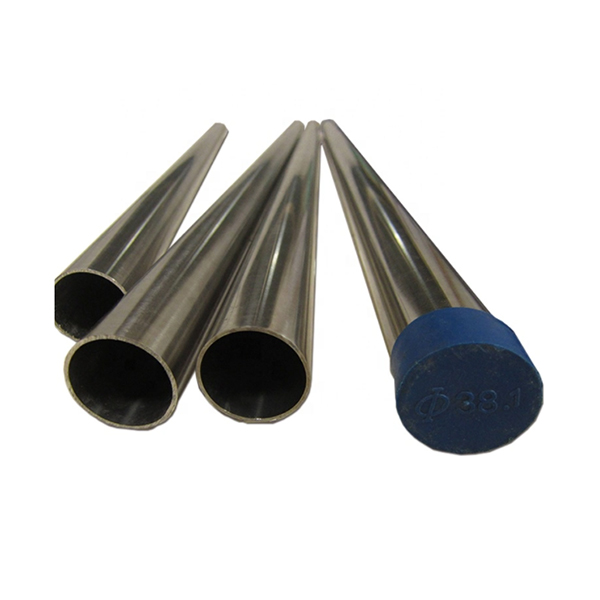

Product Display

carry on to improve, to ensure merchandise quality in line with market and shopper standard prerequisites. Our firm has a high quality assurance program are actually established for Well-designed 3lpe Oil Pipeline Liquid Epoxy Anti Corrosion Plastic Coated Spiral Welded Steel Pipe, For additional queries or should you might have any question regarding our goods, make sure you do not hesitate to call us.

Well-designed China Liquid Epoxy Anti-Corrosion Pipe and Plastic Coated Anticorrosive Pipe, Custom orders are acceptable with different quality grade and customer’s especial design. We’ve been looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.