Stainless Steel Square Rectangle Pipe

Stainless Steel Square Tube is one form of the pipes. There are round, square, rectangular, hexagonal and hydraulic pipe types in the stainless steel varieties.There are 304, 316 grades of austenitic stainless steels that are mostly used in industries. There are also other types of stainless steel pipes such as duplex, ferritic, martensitic and alloy steel materials.

Stainless steel square tube and rectangular tube is commonly referred to as tube steel or structural tubing. These are also referenced as a hollow structural section or HSS for short. Used for structural purposes, square tube, rectangular tube, I beams, etc., can be purchased in many different types of steel and alloys. Manufacturing of square tube is the same as the manufacturing process of pipe but the product goes through a series of shaping stands, meeting its final square specifications.

The square cross section of the tubes provides good geometric strength. The pipes are therefore used in high strength applications. There are high pressure and high temperature services such as the heat exchangers which use the pipes as well. The 316 ss square tubing is strong and corrosion resistant. The 316 material has chromium, nickel and molybdenum in the composition. This combination allows for increased corrosion resistance with 215MPa minimum yield strength 505MPa minimum tensile strength. The tubes can also operate under temperatures up to 870 degrees Celsius. The SS Square Welded Tube has use cases in the oil and gas, petroleum, petrochemical, construction and in structural applications as well. There are higher grades such as the SS317 Square Tubes which are made of the 317 grade material which has 517MPa minimum tensile strength. It is useful in high strength demanding applications. The ASTM A270 Seamless Square Tube is used in high pressure, high temperature services as well as general corrosive services too.

Stainless Steel Seamless Square Tubing, The Production Process

Round steel preparation → heating → hot rolling perforation → cutting head → pickling → polishing → lubrication → cold rolling process → degreasing → solution heat treatment → straightening → pipe cutting → pickling → finished product inspection.

Stainless Steel Seamless Square Tubing ,Performance Analysis

The metal can react with oxygen in the atmosphere to form an oxide film on the surface. The iron oxide formed on ordinary carbon steel will continue to oxidize, expanding the corrosion and eventually forming holes. This can be done using paint or an oxidation-resistant metal plating to protect the surface of carbon steel, but this coating is only a thin film. If the coating is damaged, the steel underneath begins to rust again. Whether the stainless steel tube is corroded is related to the chromium content in the steel. When the chromium content in the steel reaches 12%, the surface of the stainless steel tube generates a layer of passivation and dense chromium rich oxide to protect the surface and prevent further reoxidation. This oxide layer is extremely thin, through which the natural sheen of the steel surface can be seen, giving stainless steel a unique surface. If the chromium film is damaged once, the chromium in the steel and the oxygen in the atmosphere to regenerate the passivation film, continue to play a protective role. In some special environments, stainless steel will also appear some local corrosion and failure, but stainless steel and carbon steel is different, will not appear uniform corrosion and failure, so the corrosion allowance for stainless steel tube is meaningless.

Specifications

| Product Name | Stainless Steel Seamless Pipe | |

| Steel grade | 300 series | |

| Standard | ASTM A213, A312, ASTM A269, ASTM A778, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 | |

| Material | 304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 304N, 3 16L, 316N, 201, 202 | |

| Surface | Polishing, annealing, pickling, bright | |

| Type | hot rolled and cold rolled | |

| stainless steel square pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 4mm*4mm-800mm*800mm | |

| stainless steel rectangular pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8"-100") | |

| Length | 4000mm, 5800mm, 6000mm, 12000mm, or as required. | |

| Trade terms | Price terms | FOB, CIF, CFR, CNF, Ex-work |

| Payment terms | T/T, L/C, westen union | |

| Delivery time | Prompt delivery or as the order quantity. | |

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Italy, India, Egypt, Oman, Malaysia, Kuwait, Canada, Viet Nam, Peru, Mexico, Dubai, Russia, etc | |

| Package | Standard export seaworthy package, or as required. | |

| Application | Widely used in petroleum, foodstuff, chemical industry, construction, electric power, nuclear, energy, machinery, biotechnology, paper making, shipbuilding, boiler fields. Pipes also can be made according to the customer's required. |

|

| Contact | If you have any questions, please feel free to contact me. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

Chemical Composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

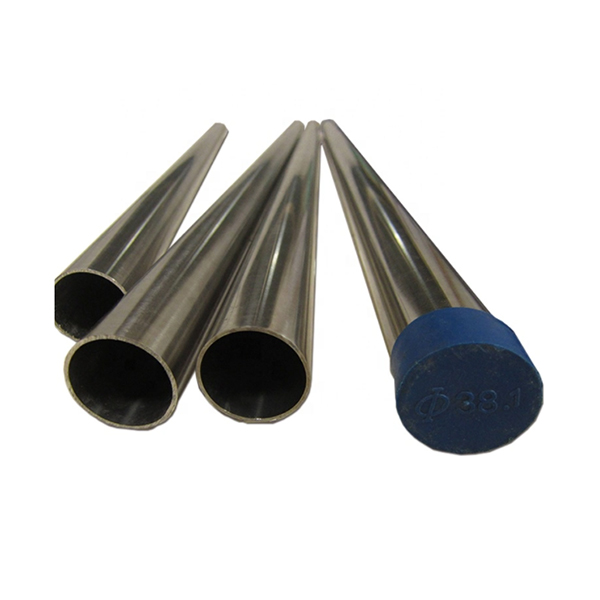

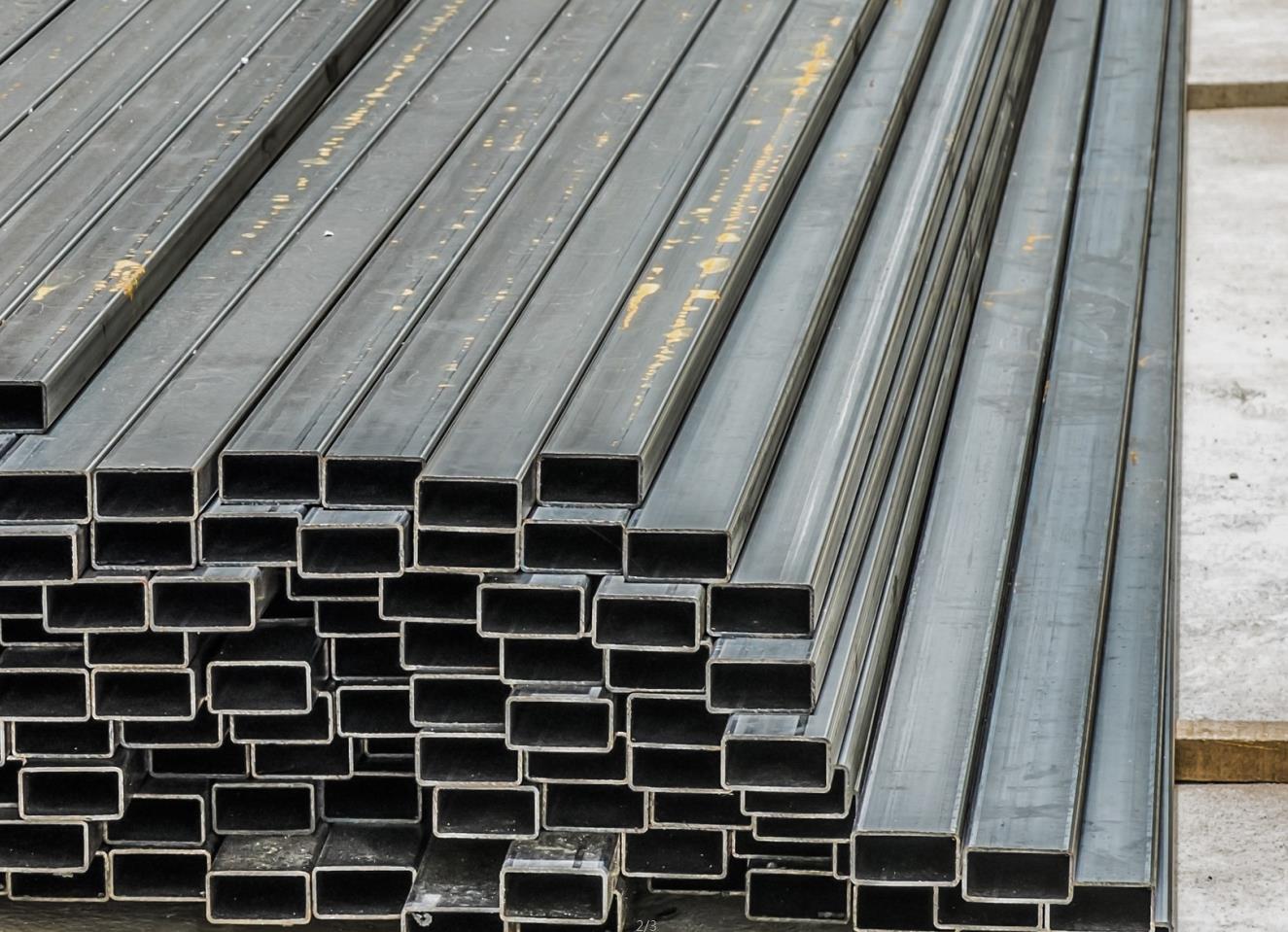

Product Display