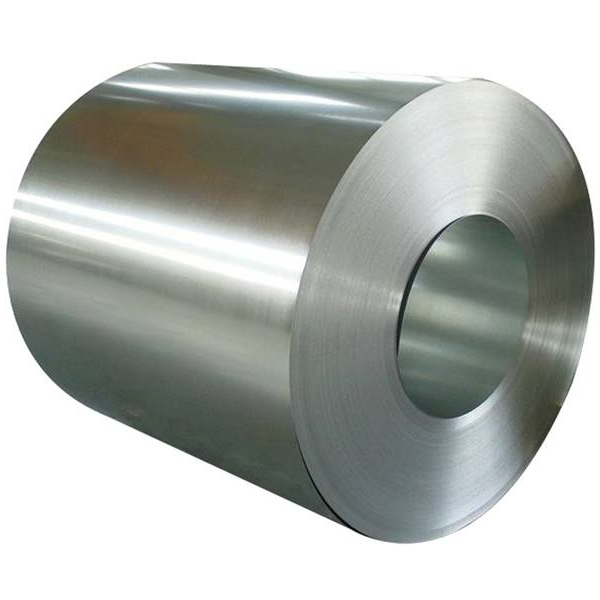

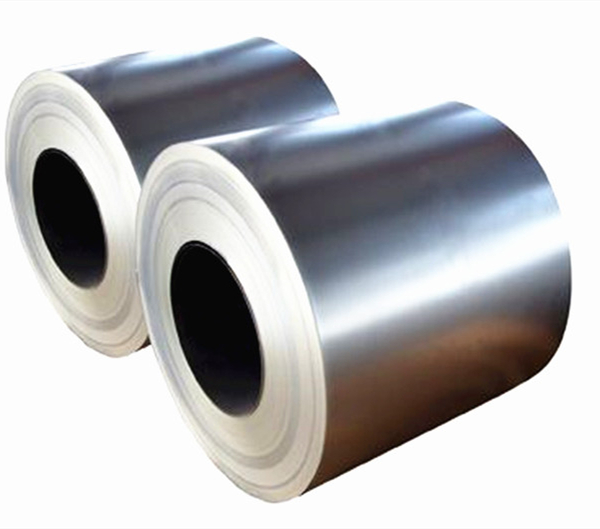

stainless steel belt

The stainless steel strip is simply an extension of the ultra-thin stainless steel plate. It is mainly a kind of narrow and long steel plate to meet the needs of industrial production of various kinds of metal or mechanical products in different industrial sectors.

Types of stainless steel belts

There are many types of stainless steel belts, which are widely used: 201 stainless steel belts, 202 stainless steel belts, 304 stainless steel belts, 301 stainless steel belts, 302 stainless steel belts, 303 stainless steel belts, 316 stainless steel belts, J4 stainless steel belts, 309S stainless steel belts, 316L stainless steel belts, 317L stainless steel belt, 310S stainless steel belt, 430 stainless steel iron belt, etc.! Thickness: 0.02mm-4mm, width: 3.5mm-1550mm, can be customized!

Stainless steel belt domestic (imported) stainless steel belt: stainless steel coil belt, stainless steel spring belt, stainless steel stamping belt, stainless steel precision belt, stainless steel mirror belt, stainless steel cold-rolled belt, stainless steel hot-rolled belt, stainless steel etching belt, stainless steel stretching belt, stainless steel Polishing belt, stainless steel soft belt, stainless steel hard belt, stainless steel medium hard belt, stainless steel high-temperature belt, etc.

The properties of stainless steel belts

Like other materials, the physical properties of stainless steel strip mainly include the following three aspects: thermodynamic properties such as melting point, specific heat capacity, thermal conductivity, and linear expansion coefficient, electromagnetic properties such as resistivity, electrical conductivity, and magnetic permeability, and Young's modulus of elasticity, stiffness coefficient, and other mechanical properties. These properties are generally considered to be inherent properties of stainless steel materials but are also affected by factors such as temperature, degree of processing, and magnetic field strength. Generally speaking, stainless steel has lower thermal conductivity and higher resistance than pure iron, and the properties such as linear expansion coefficient and magnetic permeability vary according to the crystal structure of stainless steel itself.

The physical properties of the main grades of martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, precipitation hardening stainless steel, and duplex stainless steel are listed in Table 4-1 to Table 4-5. Such as density, melting point, specific heat capacity, thermal conductivity, coefficient of linear expansion, resistivity, magnetic permeability, longitudinal elastic coefficient, and other parameters.

Specifications

| Product Name | stainless steel belt | |

| Standard | ASTM A213, A312, ASTM A269, ASTM A778, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 | |

| Material | 304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 304N, 3 16L, 316N, 201, 202 | |

| stainless steel belt | ||

| Trade terms | Price terms | FOB, CIF, CFR, CNF, Ex-work |

| Payment terms | T/T, L/C, westen union | |

| Delivery time | Prompt delivery or as the order quantity. | |

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Italy, India, Egypt, Oman, Malaysia, Kuwait, Canada, Viet Nam, Peru, Mexico, Dubai, Russia, etc | |

| Package | Standard export seaworthy package, or as required. | |

| Application | Widely used in petroleum, foodstuff, chemical industry, construction, electric power, nuclear, energy, machinery, biotechnology, paper making, shipbuilding, boiler fields. | |

| Contact | If you have any questions, please feel free to contact me. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

Chemical Composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Product Display