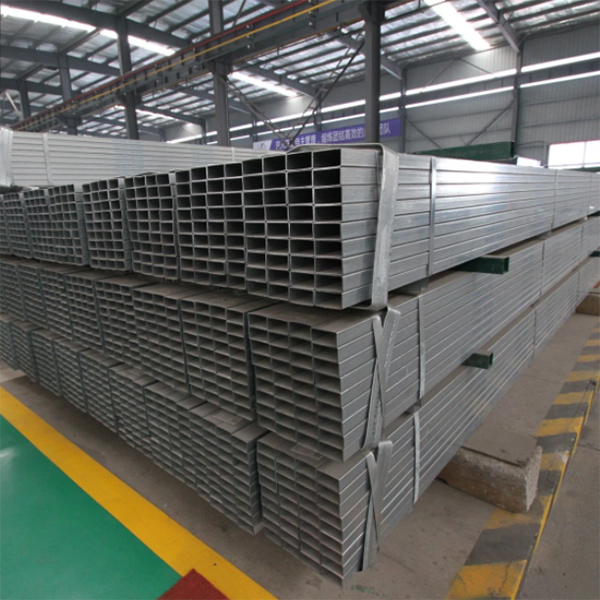

Quality Inspection for Steel Square Pipe - L360 pipeline steel custom processing pipeline transport pipe – Zheyi

Quality Inspection for Steel Square Pipe - L360 pipeline steel custom processing pipeline transport pipe – Zheyi Detail:

L360 Pipeline Steel, Purpose: API SPEC 5L-2011 (Pipeline Specification), developed and published by the American Petroleum Institute, is used worldwide. Pipepipe: To transport oil, gas or water off the ground through pipepipes to the oil and gas industry. Pipeline pipe includes seamless and welded pipe two kinds, the pipe end has flat end, threaded end and socket end; The connection mode is end welding, hoop connection, socket connection and so on. The main material of the tube is B, X42, X46, X56, X65, X70 and other steel grade. Our company passed the API certification (API 5CT and API 5L) in August 2009.

L360 Pipeline Steel, API SPEC 5L GB/T9711.1 GB/T9711.2 China National Standard Application: Oxygen, water and oil delivery pipes in the oil and natural gas industry B, X42, X52, X60, X65, X70 L245 L290 L320 L360 L390 L450 L485

With the development of the pipeline steel plate technology and the progress of welded pipe forming, welding technology, the application range of the pipe with welded pipe in gradually expanding, especially in the large diameter welded pipe class scope advantages more apparent, and cost factors, welded pipe has been dominant in the field of line pipe, which limits the development of stainless steel seamless steel line pipe. In 2004, the output of seamless pipeline is about 400,000 t, steel grade includes X42-70, and the varieties are onshore pipeline and submarine pipeline.

The production of high steel grade pipeline pipe adopts microalloying heating treatment process, the production cost of stainless steel seamless pipe is obviously higher than welded pipe, and with the improvement of steel grade, such as X80 and above steel grade pipeline pipe limit on carbon equivalent, the conventional process of seamless pipe is difficult to meet the requirements of users; Each 12Cr1moV alloy pipe manufacturer is carrying out scientific research work in order to improve the corrosion resistance of its pipeline pipe and the stable performance in low and high temperature environment.

L360 Pipeline Steel, The Material

L245, L360, A53, J55, N80, X42, X46, X52, X56, X60, X65, X70

L360 Pipeline Steel, Specifications

∮60-630×1.53-40

L360 Pipeline Steel, Mechanical Properties

| standard | brand | Tensile strength(MPa) | The yield strength(MPa) | showed | elongation(%) |

0 ℃ impact energy Akv (J)

|

Heat treatment condition |

| API SPEC 5L

GB/T9711.2 |

B | ≥415 | 245~440 | ≤0.80 | 22 | ≥40 | Is the fire |

| X42 | ≥415 | 290~440 | ≤0.80 | 21 | ≥40 | Is the fire | |

| X52 | ≥460 | 360~510 | ≤0.85 | 20 | ≥40 | Is the fire | |

| X60 | ≥520 | 415~565 | ≤0.85 | 18 | ≥40 | Is the fire | |

| X65 | ≥535 | 450~570 | ≤0.90 | 18 | ≥40 | Quenching + tempering | |

| X70 | ≥570 | 485~605 | ≤0.90 | 18 | ≥40 | Quenching + tempering |

L360 Pipeline Steel, Chemical Composition

| standard | brand | Chemical composition (%) | CEV(%) | |||||||

| C | Si | Mn | P | S | V | Nb | Ti | |||

| API SPEC 5L

GB/T9711.2 |

B | ≤0.16 | ≤0.40 | ≤1.10 | ≤0.020 | ≤0.010 | - | - | - | ≤0.42 |

| X42 | ≤0.17 | ≤0.40 | ≤1.20 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.05 | ≤0.04 | ≤0.42 | |

| X52 | ≤0.20 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.10 | ≤0.05 | ≤0.04 | ≤0.45 | |

| X60 | ≤0.21 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.15 | ≤0.05 | ≤0.04 | 协议 | |

| X65 | ≤0.16 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 | |

| X70 | ≤0.16 | ≤0.45 | ≤1.70 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 |

Note: 1.0.015% ≤Altot< 0.06%; N 0.012% or less; Al/N 2/1 or higher; Cu 0.25% or less. Ni 0.30% or less. Cr 0.30% or less; Mo≤0.10% 2.V +Nb+Ti≤0.15 3.X60, X65, X70 As agreed Mo≤0.35% API SPEC 5L

Product Display

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Quality Inspection for Steel Square Pipe - L360 pipeline steel custom processing pipeline transport pipe – Zheyi , The product will supply to all over the world, such as: Georgia, New Delhi, Peru, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Problems can be quickly and effectively resolved, it is worth to be trust and working together.