PriceList for Asme B36 10 - C7025 Brass name brand manufacturer’s ex-factory price – Zheyi

PriceList for Asme B36 10 - C7025 Brass name brand manufacturer’s ex-factory price – Zheyi Detail:

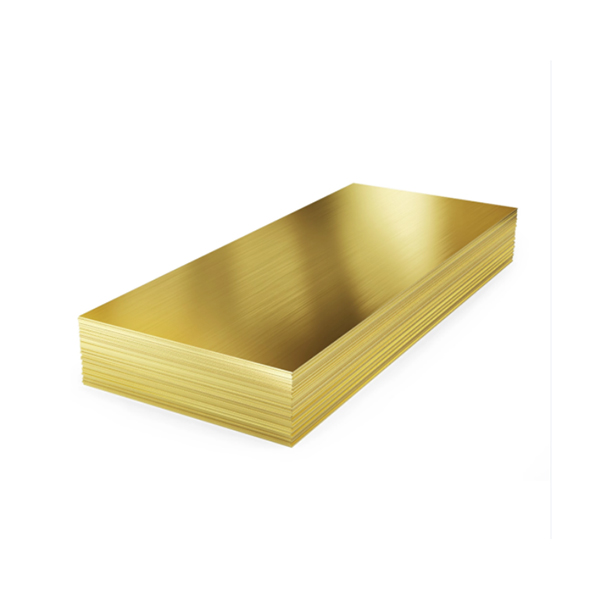

C7025 Brass Plate, is a widely used lead brass, has good mechanical properties, and good machinability, can withstand cold and hot pressure processing, used in cutting and stamping of various structural parts, such as gaskets, bushings, etc.. Tin brass plate has high corrosion resistance, good mechanical properties, good pressure workability in cold and hot states, can be used for corrosion resistant parts on ships and steam, oil and other media contact parts and conduit.

C7025 Brass Plate, Features

C7025 Brass Plate,It’s an alloy of copper and zinc. The simplest brass is a copper-zinc binary alloy called simple brass or plain brass. Different mechanical properties of brass can be obtained by changing the content of zinc in brass. The higher the content of zinc in brass, its strength is higher, slightly lower plasticity. The zinc content of brass used in industry is not more than 45%, and the higher zinc content will produce brittleness, so that the alloy performance deteriorates. In order to improve the performance of brass, the brass with other alloying elements is called special brass. Common alloying elements include silicon, aluminum, tin, lead, manganese, iron and nickel. The yield strength and corrosion resistance of brass can be improved by adding aluminum to brass, and the plasticity can be reduced slightly. Brass containing less than 4% aluminum has good processing, casting and other comprehensive properties. Adding 1% tin to brass can significantly improve the ability of brass to resist sea water and Marine atmospheric corrosion, so it is called “naval brass”. Tin can also improve the machining performance of brass. The main purpose of adding lead to brass is to improve the machinability and wear resistance. Lead has little effect on the strength of brass. Manganese brass has good mechanical properties, thermal stability and corrosion resistance. The properties of manganese brass can be improved by adding aluminum to it, and the casting with smooth surface can be obtained. Brass can be divided into casting and pressure – working products.

Have good mechanical properties, hot plastic good, cold plastic can also be good, good machinability, easy fiber welding and welding, corrosion resistance, but easy to produce corrosion crack, in addition to the price is cheap, is the most widely used in a common brass variety.

C7025 Brass Plate, Product History

Since we do not know what method the ancient people used to smelt zinc ore or zinc ore, the situation of the ancient use of H62 brass plate is not very clear. Zinc has a lower boiling point than copper, and when the copper is heated, the charcoal also heats the zinc ore, making it difficult to keep the zinc from evaporating. The Romans may have been the first to use this method on a large scale, but bronze smelters may have inadvertently produced H62 brass plates earlier, since the distinction between tin and zinc was initially unclear. We should note that the H62 brass plate mentioned in the Bible is actually bronze; Roman coins, called aes, were also made of copper or bronze, not H62 brass plates. To complicate matters, they did use H62 plates for coins, but H62 plates were initially more expensive than either copper or bronze.

From the Middle Ages, however, before they were used as POTS and pans, H62 brass was a luxury, used only for things like commemorative tombstones. H62 brass plates were popular in Europe for about 300 years, from about 1230 AD, because they were much cheaper than large sculptures. The statue of Archbishop Wilpe, who died in 1231, is the earliest known bronze statue made from H62 brass plates. The process of casting H62 brass plate products is as follows: ground zinc ore and charcoal are mixed with copper blocks and heated to make the zinc and copper join together, then heated to melt the alloy, and then molten copper is poured into the mold. The earliest British H62 brass plates were imported, mainly from Tournay. Clients can order complete headstones from Tournay, already mounted on beautiful backboards or marble plinths.

Specification

| Product Name | C7025 Brass Plate |

| Thickness | 0.1mm-120mm |

| Material | T1,T2,C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, TP1,TP2,C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, TU1,TU2,C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000,C44300, C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70600,C70620,C71000, C71500,C71520,C71640,C72200,etc |

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,etc |

| Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

| Surface | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

| Application | 1. Pancake Coil for ACR, General Engineering Applications 2. LWC Coil for ACR, General Engineering Applications 3. Straight Copper Tubes for ACR and Refrigeration 4. Inner-grooved copper tube for ACR and Refrigeration 5. Copper Pipe for Transportation System of water, gas and oil 6.PE-coated copper tube for water/gas/oil transportation system 7.Semi-finished Copper tube for industrial applications |

Product Display

Product detail pictures:

Related Product Guide:

We keep on with the theory of "quality first, provider initially, constant improvement and innovation to meet the customers" with the management and "zero defect, zero complaints" as the standard objective. To great our company, we deliver the merchandise using the fantastic excellent at the reasonable price for PriceList for Asme B36 10 - C7025 Brass name brand manufacturer’s ex-factory price – Zheyi , The product will supply to all over the world, such as: Comoros, Guatemala, Boston, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.