OEM Customized 16mo3/15mo3 Alloy Steel Seamless Finned Tube

Our solutions are widely identified and trusted by people and might fulfill continuously transforming economic and social demands for OEM Customized 16mo3/15mo3 Alloy Steel Seamless Finned Tube, Our ultimate objective is always to rank as a top brand and to lead as a pioneer within our field. We have been sure our thriving experience in tool generation will win customer’s trust, Wish to co-operate and co-create a far better potential along with you!

Our solutions are widely identified and trusted by people and might fulfill continuously transforming economic and social demands for China 16mo3 Finned Tube and Alloy Steel Finned Pipe, Now, we professionally supplies customers with our main products And our business is not only the “buy” and “sell”, but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

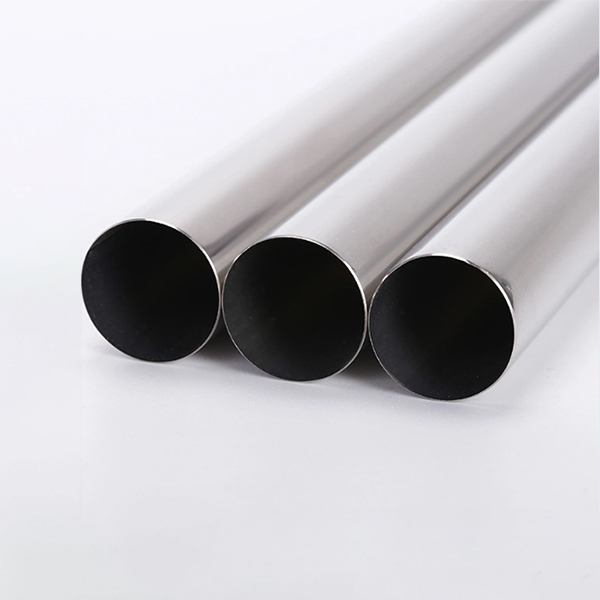

TA2 Titanium Alloy Pipe, Advantages

TA2 Titanium Alloy Pipe,Compared with other metal materials, it has the following advantages:

1. High specific strength (tensile strength/density) (see figure), the tensile strength can reach 100 ~ 140kgf/mm2, while the density is only 60% of steel.

2. The medium temperature strength is good, the use temperature is several hundred degrees higher than aluminum alloy, in the medium temperature can still maintain the required strength, can work in 450 ~ 500℃ temperature for a long time.

3. Good corrosion resistance, titanium surface in the atmosphere immediately formed a layer of uniform and dense oxide film, has the ability to resist a variety of media erosion. Titanium generally has good corrosion resistance in oxidizing and neutral media, especially in seawater, wet chlorine and chloride solutions. But in reducing medium, such as hydrochloric acid solution, titanium corrosion resistance is poor.

4. Titanium alloys with good low temperature performance and very low clearance elements, such as TA7, can maintain certain plasticity at -253℃.

5. Low elastic modulus, small thermal conductivity, no ferromagnetism.

6. High hardness.

7. Poor stamping property and good thermoplasticity.

Heat treatment Titanium alloy can obtain different phase composition and microstructure by adjusting heat treatment process. It is generally considered that fine equiaxed microstructure has good plasticity, thermal stability and fatigue strength. The acicular structure has higher durable strength, creep strength and fracture toughness. Equiaxed and acicular mixed structures have better comprehensive properties.

TA2 Titanium Alloy Pipe, The commonly used heat treatment methods are annealing, solution and aging treatment. Annealing is to eliminate internal stress, improve plasticity and microstructure stability, in order to obtain better comprehensive properties. Generally, the annealing temperature of α alloy and (α+β) alloy is 120 ~ 200℃ below the transition point of (α+β) — →β phase. The solution and aging treatment is to obtain the α ‘phase and the metastable β phase of martensite by fast cooling in the high temperature region, and then decompose these metastable phases by holding in the middle temperature region, and obtain the fine dispersed second phase particles, such as α phase or compound, to achieve the purpose of strengthening the alloy. Usually (alpha + beta) alloy quenching in alpha + beta) — – > beta phase transition point below 40 ~ 100 ℃, metastable beta alloy quenching in alpha + beta) — – > beta phase transition point above 40 ~ 80 ℃. The aging temperature is generally 450 ~ 550℃. In addition, in order to meet the special requirements of the workpiece, the industry also uses double annealing, isothermal annealing, β heat treatment, deformation heat treatment and other metal heat treatment process.

TA2 Titanium Alloy Pipe, Classification

Titanium pipe, titanium welding pipe, titanium splicing tee, titanium splicing elbow, titanium welding ring, titanium reducing, titanium tee, titanium elbow, titanium chimney, etc.

TA2 Titanium Alloy Pipe, The Working Principle Of

TA2 Titanium Alloy Pipe, Mainly connecting all kinds of titanium equipment pipeline, used for material circulation between all kinds of equipment, the pipeline has the corrosion resistance of titanium material itself, so as to replace the general pipeline for ordinary pipeline can not meet the demand. Generally ф 108 above are welded pipes.

Main Technical Parameters

| DN(mm) | Measuring the outer diameter(mm) | The material |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

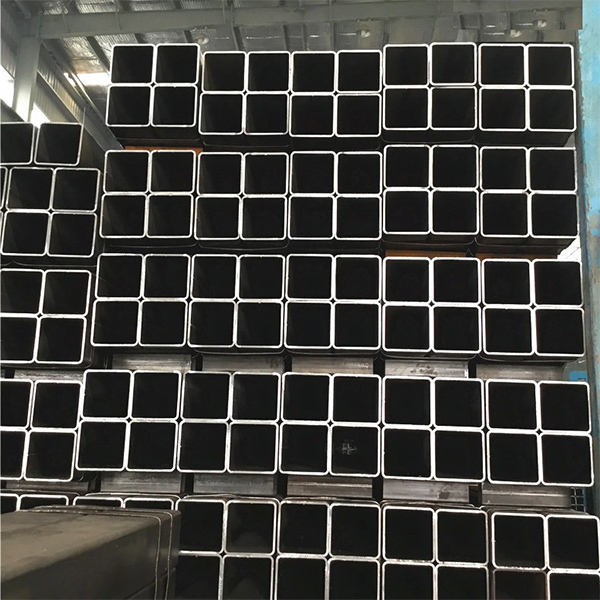

Product Display

Our solutions are widely identified and trusted by people and might fulfill continuously transforming economic and social demands for OEM Customized 16mo3/15mo3 Alloy Steel Seamless Finned Tube, Our ultimate objective is always to rank as a top brand and to lead as a pioneer within our field. We have been sure our thriving experience in tool generation will win customer’s trust, Wish to co-operate and co-create a far better potential along with you!

OEM Customized China 16mo3 Finned Tube and Alloy Steel Finned Pipe, Now, we professionally supplies customers with our main products And our business is not only the “buy” and “sell”, but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.