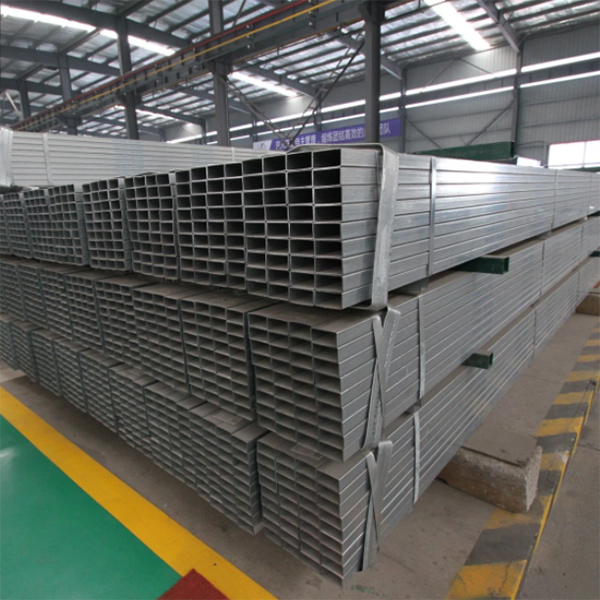

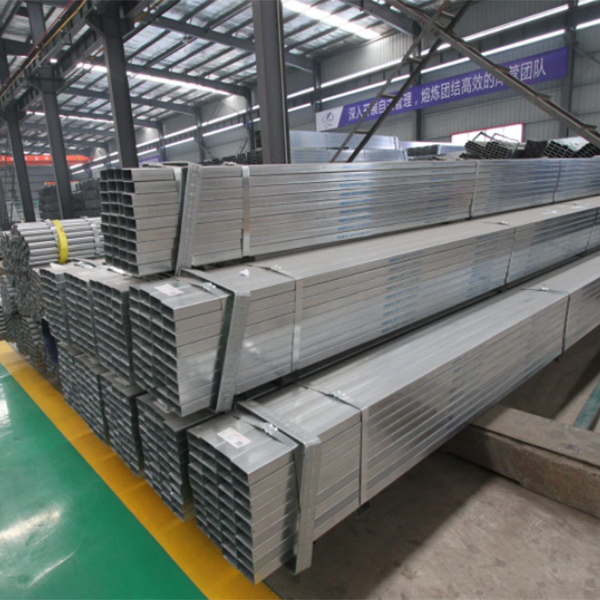

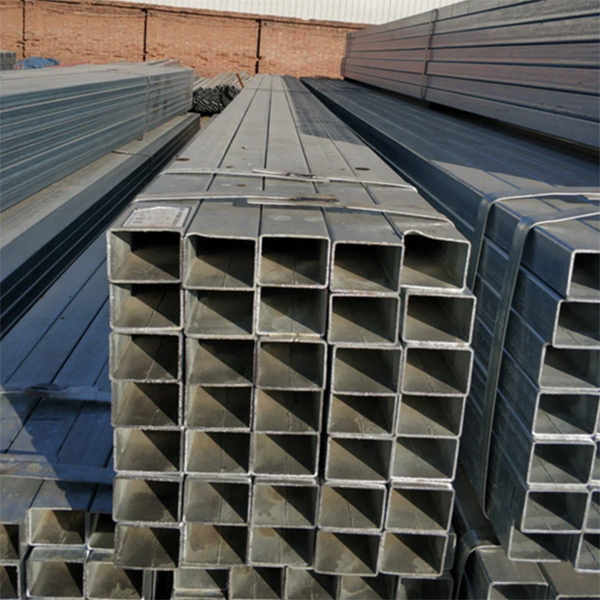

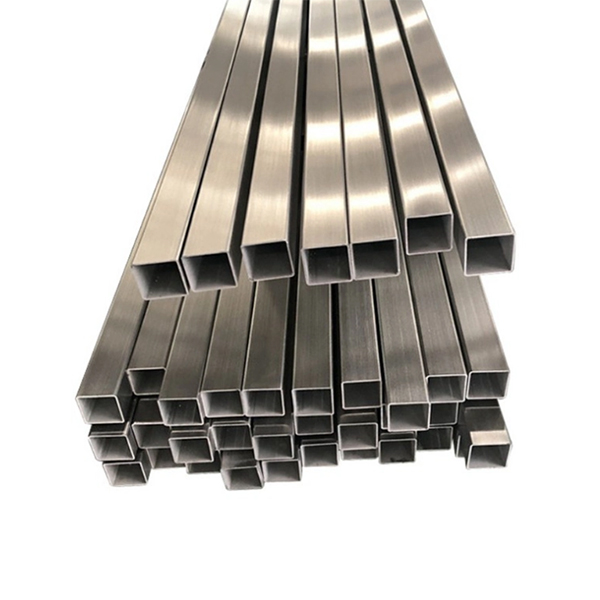

Manufacturer of galvanized square steel pipe for guardrail pipe

Galvanized square pipe from the production process is divided into hot dip galvanized square pipe and cold galvanized square pipe. It is because of the different processing of these two galvanized square tubes that they have many different physical and chemical properties. In general, there are many differences in strength, toughness and mechanical properties.

Hot dip galvanized square pipe

Hot-dip galvanized square tube is a square tube made of steel plate or steel belt crimped and welded. On the basis of this square tube, the square tube is placed in the hot-dip galvanized pool and formed after a series of chemical reactions. The production process of hot-dip galvanized square pipe is relatively simple, and the production efficiency is very high, and the varieties and specifications are also many. This square pipe requires little equipment and capital, which is suitable for the production of small galvanized square pipe manufacturers. But from the strength of the steel tube strength is far lower than seamless square tube.

Cold galvanized square pipe

Cold galvanized square pipe is in the use of the principle of cold galvanized square pipe to have corrosion resistance. Different from hot dip galvanized cold galvanized coating is mainly anticorrosive through the principle of electrochemistry, so it is necessary to ensure sufficient contact between zinc powder and steel, resulting in electrode potential difference, so the steel surface treatment is very important.

Features

1. Size: 15mmx15mm-300x300mm

2. Material: Carbon steel

3. Factory price

4. Do small order

Specifications

| Item | galvanized square steel tube |

| material | Q235B/Q345b/Ss400/A36/St37 |

| certifications | ISO9001 /SGS |

| standard | ASTM BS GB API |

| size(dia) | 15*15mm-300*300mm |

| item | black rectangular section pipe |

| size | 10*20mm-200*400mm |

| technique | welded ,ERW ,cold rolled .hot rolled |

| surface | Bared, Galvanized, Oiled,Or Other Anti-corrosive Treatment.We can produce other specifications according to customers requirements. |

| packaging |

1.Big OD:in bulk 2.Small OD:packed by steel strips 3. 20"GP:5.85*2.2*2.2 40"GP:11.85*2.2*2.2 Black steel pipe: oiled/painted, in bundles and tarpaulin outside According to the requirements of customers |

| inspection | With Chemical Composition and Mechanical Properties Analysis;Hydrostatic Test, Dimensional and Visual Inspection, Also With Nondestructive Inspection |

| Usage/Application | Mechanical & manufacture, Steel structure, Shipbuilding, Bridging ,Automobile chassisIndustrial water lines/plant piping, Vehicular chassis and frames, Idlers & belt conveyorsAgriculture and Irrigation, Scaffoldings, Electrical Cable conduits, Cooling towers, Antenna and Telecom Towers, Cold storages, Tabular polesFire Protection Systems, HVAC, Plumbing,Fabrication industry, |

| main market | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| country of origin | china |

| Productivity | 5000tons per month |

| delivery time | within 15 working days after receiving the payment or 100% Irrevocable L/C at sight |

Pipe/ Tube Specifications

| Size(mm) | Thickness(mm) | Size(mm) | Thickness(mm) | Size(mm) | Thickness (mm) | Size(mm) | Thickness (mm) |

| 20*20 | 1.0 | 60*60 50*70 40*80 50*80 70*70 60*80 100*40 |

1.3 | 120*120 140*80 160*80 75*150 100*150 160*60 |

2.5-2.75 | 33*450 300*500 400*400 |

4.5-5.75 |

| 1.3 | 1.4 | 3.0-4.0 | 7.5-11.75 | ||||

| 1.4 | 1.5 | 4.25-4.75 | 12.5-13.75 | ||||

| 1.5 | 1.7 | 5.25-6.0 | 14.5-14.75 | ||||

| 1.7 | 1.8 | 6.5-7.75 | 15.5-17.75 | ||||

| 2.0 | 2.0 | 9.5-15 | 450*450 200*600 300*600 400*500 400*600 500*500 |

4.5-4.75 | |||

| 25*25 20*30 |

1.3 | 2.2 | 130*130 80*180 140*140 150*150 200*100 |

2.5-2.75 | 7.5-7.75 | ||

| 1.4 | 2.5-4.0 | 3.0-3.25 | 9.5-9.75 | ||||

| 1.5 | 4.25-5.0 | 3.5-4.25 | 11.5-13.75 | ||||

| 1.7 | 5.25-6.0 | 4.5-9.25 | 14.5-15.75 | ||||

| 1.8 | 9.5-15 | 16.5-17.75 | |||||

| 2.0 | 90*90 75*75 80*80 60*90 60*100 50*100 60*120 50*120 80*100 |

1.3 | 160*160 180*180 250*100 200*150 |

2.5-2.75 | |||

| 2.2 | 1.5 | 3.5-5.0 | |||||

| 2.5-3.0 | 1.7 | 5.25-7.75 | |||||

| 30*30 20*40 30*40 25*40 |

1.3 | 1.8 | 9.5-15 | ||||

| 1.4 | 2.0 | 150*250 100*300 150*300 200*200 135*135 |

2.75 | ||||

| 1.5 | 2.2 | 3.0-3.25 | |||||

| 1.7 | 2.5-4.0 | 3.5-7.75 | |||||

| 1.8 | 4.25-5.0 | 9.5-12.5 | |||||

| 2.0 | 5.25-5.75 | 12.75-15.75 | |||||

| 2.2 | 7.5-7.75 | 200*300 250*250 100*400 200*250 |

3.52-3.75 | ||||

| 2.5-3.0 | 100*100 80*120 125*75 140*60 50*150 |

1.5 | 4.5-11.75 | ||||

| 25*50 40*40 30*50 30*60 40*50 40*60 50*50 |

1.3 | 1.7 | 12.5-14.75 | ||||

| 1.4 | 1.8 | 15.5-17.75 | |||||

| 1.5 | 2.0 | 200*350 200*400 300*300 250*350 |

4.75-7.75 | ||||

| 1.7 | 2.2 | 9.5-11.75 | |||||

| 1.8 | 2.5-5.0 | 12.5-14.75 | |||||

| 2.0 | 5.25-6.0 | 15.5-17.75 | |||||

| 2.2 | 6.5-7.75 | 300*350 300*400 350*350 250*450 |

4.75-7.75 | ||||

| 2.5-4.0 | 9.5-13 | 9.5-11.75 | |||||

| 4.25-5.0 | 12.5-14.75 |

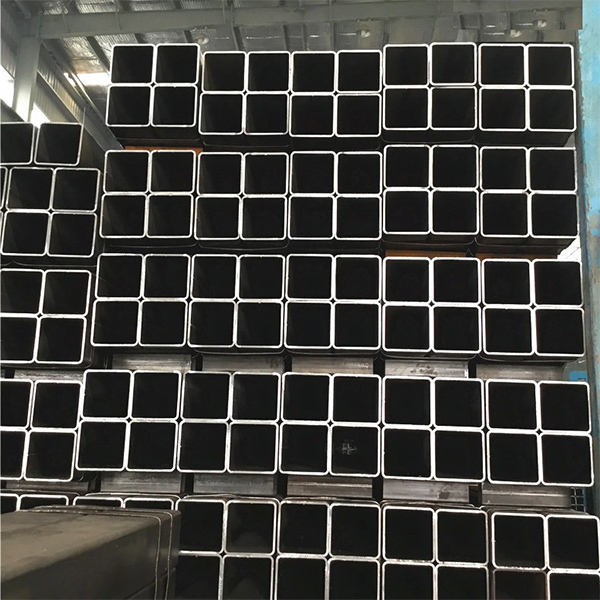

Product Display