High Quality Alloy Steel Pipe - Titanium alloy TA3 tube factory direct processing can be customized – Zheyi

High Quality Alloy Steel Pipe - Titanium alloy TA3 tube factory direct processing can be customized – Zheyi Detail:

Titanium Alloy TA3 Tube, Classification

Titanium pipe, titanium welding pipe, titanium splicing tee, titanium splicing elbow, titanium welding ring, titanium reducing, titanium tee, titanium elbow, titanium chimney, etc.

Titanium Alloy TA3 Tube, The Working Principle Of

Titanium Alloy TA3 Tube, Mainly connecting all kinds of titanium equipment pipeline, used for material circulation between all kinds of equipment, the pipeline has the corrosion resistance of titanium material itself, so as to replace the general pipeline for ordinary pipeline can not meet the demand. Generally ф 108 above are welded pipes.

Titanium Alloy TA3 Tube, Product Feature

1. Excellent corrosion resistance in many media

2. Low density, high strength, small weight of equipment

3. The surface is smooth and clean, without dirt, and the dirt coefficient is greatly reduced

Titanium Alloy TA3 Tube, Range Of Application

Titanium Alloy TA3 Tube, Widely used in chemical, petroleum, metallurgy, light industry machinery, instrumentation, power generation, seawater desalination, medical equipment, chlor-alkali salt, electroplating, environmental protection, copper industry and other industries.

Titanium Alloy TA3 Tube, Performance

Titanium Alloy TA3 Tube, is a new type of metal, titanium performance and the content of carbon, nitrogen, hydrogen, oxygen and other impurities, the purest titanium iodide impurity content is not more than 0.1%, but its low strength, high plasticity. The properties of 99.5% industrial pure titanium are as follows: density ρ=4.5g/ cc, melting point 1725℃, thermal conductivity λ=15.24W/(m.K), tensile strength σb=539MPa, elongation δ=25%, area reduction ψ=25%, elastic modulus E=1.078×105MPa, hardness HB195

| Commodity: | Titanium Alloy TA3 Tube |

| Process method: | Cold rolled/ Cold drawn |

| Materials Grades: | TA0,TA1,TA2,TA9,TA10,BT1-00,BT1-0,Gr1,Gr2,Gr3,Gr4,Gr5,Gr7,Gr9, Ti6A14VELI |

| Standards: | GB/T3624-2010, GB/T3625-2007, ASTM B337/338,ASTM B861/862 |

| Size: | Length: ≤15000 mm |

| OD: 0.8-114 mm | |

| Shape: | Straight or U-bend |

| Surface Finished: | Annealed/ Mechanical Polish or as required |

| Inspection Testing: | 100% Ultrasonic Test, 100%Eddy Current Test, 100%Hydraulic Test, 100% X-Ray Test to welded pipe or as required. |

| Mechanical Test, Bend Test, Inter-granular corrosion Test. | |

| Packing: | Wooden case/ Steel framed plywood case/ simple packing. |

| Delivery Time: | As per Contract |

Chemical Composition

| Grade | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal |

Tensile Requirements

| Grade | Tensile strength(min) | Yield Strength(min) | Elongation(%) | ||

| KSI | MPa | KSI | MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr3 | 65 | 450 | 55 | 380 | 18 |

| Gr4 | 80 | 550 | 70 | 483 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

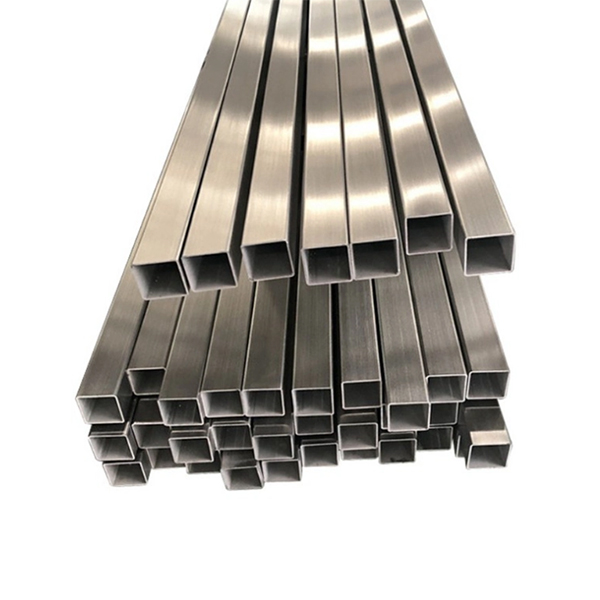

Product Display

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent excellent management throughout all stages of creation enables us to guarantee total buyer satisfaction for High Quality Alloy Steel Pipe - Titanium alloy TA3 tube factory direct processing can be customized – Zheyi , The product will supply to all over the world, such as: Danish, Dubai, Bolivia, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!