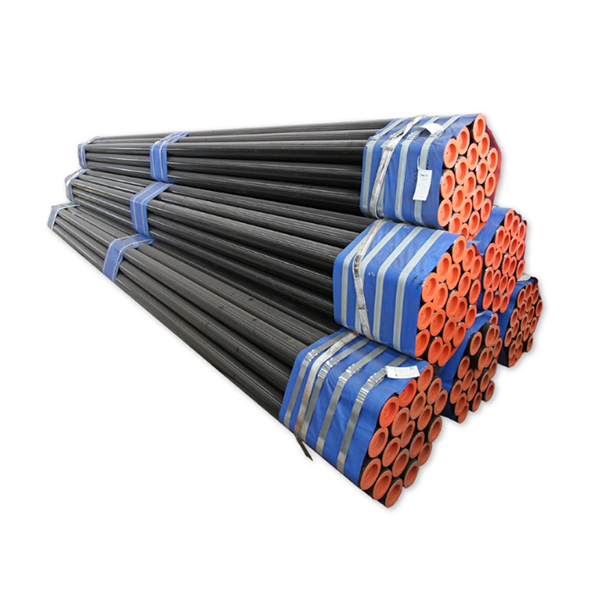

High pressure seamless tube boiler pipeline oil and gas pipe

High pressure seamless pipe,High-pressure boiler tube is a kind of boiler tube, belongs to the category of seamless steel tube. The manufacturing method is the same as seamless pipe, but there are strict requirements on the type of steel used to manufacture steel pipe. High pressure boiler tube is often used in high temperature and high pressure conditions, high pressure boiler tube is mainly used to manufacture high pressure and ultra high pressure boiler superheater tube, reheater tube, pipe, main steam pipe and so on.

Low and medium pressure boiler tube GB3087-2008, high pressure boiler tube GB5310-2008 is used to manufacture all kinds of structure low pressure boiler superheated steam tube, boiling water tube and locomotive boiler with superheated steam tube, big smoke tube, small smoke tube and arch brick pipe pipe high quality carbon structural steel hot rolled and cold drawn (rolled) seamless steel tube. Seamless steel pipe for structure (GB/T8162-2008) is used for general structure and mechanical structure of seamless steel pipe.

Specifications and appearance quality: GB5310-2008 "Seamless steel tube for high pressure boiler" hot rolled pipe diameter 22 ~ 530mm, wall thickness 20 ~ 70mm. Cold drawn (cold rolled) tube diameter 10 ~ 108mm, wall thickness 2.0 ~ 13.0mm.

Special-shaped seamless steel pipe is a general term for seamless steel pipe with other cross section shapes except circular pipe. According to the different shape and size of the steel pipe section, it can be divided into equal wall thickness special-shaped seamless steel pipe (code D), unequal wall thickness special-shaped seamless steel pipe (code BD), variable diameter special-shaped seamless steel pipe (code BJ). Special-shaped seamless steel tubes are widely used in various structural parts, tools and machinery parts. Compared with the round tube, shaped tube generally has a larger moment of inertia and section modulus, has a larger bending and torsion resistance, can greatly reduce the weight of the structure, save steel.

High Pressure Seamless Pipe, Chemical Composition

(1)GB3087-2008 "Seamless Steel pipe for Low and medium pressure boiler" provisions. Chemical composition test method according to gb222-84 and GB223 "Methods for chemical Analysis of Steel and Alloy" relevant part.

(2)GB5310-2008 "Seamless Steel Tube for high pressure boiler" provisions. Chemical composition test method according to GB222-84 and "Method for Chemical Analysis of Iron and Steel and Alloy", GB223 "Method for chemical analysis of Iron and Steel and Alloy".

(3) Chemical composition inspection of imported boiler steel pipe shall be carried out according to relevant standards stipulated in the contract.

Chemical CompositionHigh Pressure Seamless Pipe, Steel Grade

(1) High quality carbon structural steel steel 20G, 20MnG, 25MnG.

(2) Alloy structure steel 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB, etc.

(3) Rust heat resistant steel commonly used 1Cr18Ni9, 1Cr18Ni11Nb boiler tube in addition to ensure chemical composition and mechanical properties, to do water pressure test, to make flaring, compression test. Steel tubes are delivered in heat treatment condition.

In addition, the microstructure, grain size and decarburization layer of finished steel tubes are also required.

High Pressure Seamless Pipe, Physical Properties Of

(1)GB3087-82 "Seamless steel tube for low and medium pressure boiler" provisions. Tensile test according to GB/T228-87, hydraulic test according to GB/T241-90, flattening test according to GB/T246-97, flaring test according to GB/T242-97, cold bending test according to GB244-97.

(2)GB5310-95 "Seamless steel tube for high pressure boiler" provisions. Tension test, water pressure test and flattening test are the same as gb3087-82; Impact test according to GB229-94, flaring test according to GB/T242-97, grain size test according to YB/T5148-93; According to GB13298-91 for microstructure inspection, GB224-87 for decarburization layer inspection and GB/T5777-96 for ultrasonic inspection.

(3) Physical properties inspection and indicators of imported boiler tubes shall be carried out according to relevant standards stipulated in the contract.

High Pressure Seamless Pipe, Production Methods

High pressure seamless pipe,Is a kind of seamless tube. The manufacturing method is the same as seamless pipe, but there are strict requirements on the type of steel used to manufacture steel pipe. According to the use of temperature is divided into two kinds of general boiler tube and high-pressure boiler tube.

① High pressure seamless pipe,When the operating temperature is below 450℃, the domestic pipe is mainly made of no.10 and No.20 carbon bonded steel hot rolled pipe or cold drawn pipe.

② High pressure seamless pipe,When used, the pipe is often under high temperature and high pressure. Under the action of high temperature flue gas and water vapor, oxidation and corrosion will occur. The steel pipe is required to have high durable strength, high oxidation corrosion resistance and good microstructure stability.

| Standard | Steel grade | Chemical composition (%) | |||||||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V | AL | W | Nb | N | ||

| ASME SA106 |

SA106B | 0.17 ~0.25 |

≥0.1 | 0.7 ~1.0 |

≤0.03 | ≤0.03 | |||||||||

| SA106C | 0.23 ~0.27 |

≥0.1 | 0.7 ~1.0 |

≤0.03 | ≤0.03 | ||||||||||

| ASME SA333 |

SA333I | 0.09 ~0.12 |

/ | 0.7 ~1.0 |

≤0.02 | ≤0.01 | |||||||||

| SA333II | 0.09 ~0.12 |

≥0.1 | 0.9~ 1.1 |

≤0.02 | ≤0.01 | ||||||||||

| ASME

A335 |

SA335P11 | 0.05 ~0.15 |

0.5 ~1.0 |

0.3 ~0.6 |

≤0.03 | ≤0.03 | 1.0 ~1.5 |

0.5 ~1.0 |

|||||||

| SA335P12 | 0.05 ~0.15 |

≤0.5 | 0.3~ 0.6 |

≤0.03 | ≤0.03 | 0.8 ~1.25 |

0.44 ~0.65 |

||||||||

| SA335P22 | 0.05 ~0.15 |

≤0.5 | 0.3~ 0.6 |

≤0.03 | ≤0.03 | 1.9 ~2.6 |

0.87 ~1.13 |

||||||||

| SA335P5 | ≤0.15 | ≤0.5 | 0.3~ 0.6 |

≤0.03 | ≤0.03 | 4.0 ~6.0 |

0.45 ~0.65 |

||||||||

| SA335P91 | 0.08 ~0.12 |

0.2 ~0.5 |

0.3~ 0.6 |

≤0.02 | ≤0.01 | 8.0 ~9.5 |

0.85 ~1.05 |

≤0.4 | 0.18 ~0.25 |

≤0.015 | 0.06 ~0.1 |

0.03 ~0.07 |

|||

| SA335P92 | 0.07 ~0.13 |

≤0.5 | 0.3~ 0.6 |

≤0.02 | ≤0.01 | 8.5 ~9.5 |

0.3~ 0.6 |

B0.001 0.006 |

≤0.4 | 0.15 ~0.25 |

≤0.015 | 1.5 ~2.0 |

0.04 ~0.09 |

0.03 ~0.07 |

|

| DIN 17175 |

ST45.8III | ≤0.21 | 0.1 ~0.35 |

0.4 ~1.2 |

≤0.04 | ≤0.04 | ≤0.3 | ||||||||

| 15Mo3 | 0.12 ~0.2 |

0.1 ~0.35 |

0.4 ~0.8 |

≤0.035 | ≤0.035 | 0.25 ~0.35 |

|||||||||

| 13CrMo44 | 0.1 ~0.18 |

0.1 ~0.35 |

0.4 ~0.7 |

≤0.035 | ≤0.035 | 0.7 ~1.1 |

0.45 ~0.65 |

||||||||

| 10CrMo910 | 0.08 ~0.15 |

≤0.5 | 0.3 ~0.7 |

≤0.025 | ≤0.02 | 2.0 ~2.5 |

0.9 ~1.1 |

≤ 0.3 |

≤0.3 | ≤0.015 | 0.015 ~0.045 |

||||

| EN10216 -2 |

WB36 | ≤0.17 | 0.25 ~0.5 |

0.8 ~1.2 |

≤0.025 | ≤0.02 | ≤0.3 | 0.25 ~0.5 |

0.5 ~0.8 |

1.0 ~1.3 |

≤0.015 | ||||

Product Display