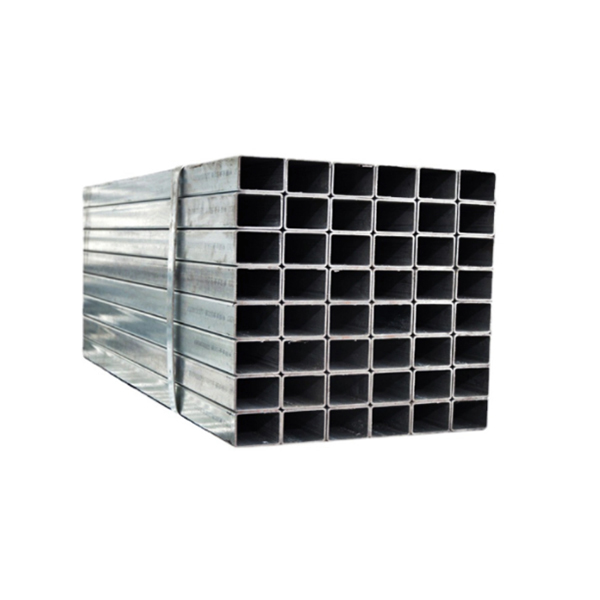

Factory Free sample Black Steel Square Tube - Square Structural Steel Tubing – Zheyi

Factory Free sample Black Steel Square Tube - Square Structural Steel Tubing – Zheyi Detail:

Square structural steel tubing, also known as welded pipe, is made of steel plate or strip after crimping forming welded square pipe.

Square structural steel tubing, Commonly used materials are: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb and so on.

Welded stainless steel pipe for decoration (GB/T 18705-2002), welded stainless steel pipe for building decoration (JG/T 3030-1995), welded steel pipe for low-pressure fluid transportation (GB/T 3091-2001), and welded steel pipe for heat exchanger (YB4103-2000).

The Production Process

Square structural steel tubing, Narrow blanks can be used to produce welded pipes with larger diameters, and blanks of the same width can be used to produce welded pipes with different diameters. But compared with the same length of straight seam square pipe, the weld length increases by 30~100%, and the production speed is lower.

Large or thick in diameter square structural steel tubing, Generally made of steel billet directly, and small welded pipe thin wall welded pipe only need to be directly welded through the steel belt. After a simple polishing, the wire is ready. Therefore, small diameter welded pipe mostly use straight seam welding, large diameter welded pipe mostly use spiral welding.

Shape The Performance

square structural steel tubing, It’s a name for square pipe, which is the pipe with the same length on both sides. It is made of strip steel through process solution and rolling. Normally, the strip is unpacked, flat, crimped, welded into a round tube, and then rolled by the round tube Q215 welded square tube and then cut into the length of demand. The normal number is 50 per pack. Strength refers to the function of resisting damage (proper plastic deformation or fracture) of Q215 welded square pipe data under static load. Because the load of the form of tensile, contraction, winding, shear and other ways, because the strength is also divided into tensile strength, compressive strength, bending strength, shear strength and so on. All kinds of strength often have definite contact, the normal use of tensile strength as the most fundamental strength needle. The strength to resist destruction is called charge toughness.

The load on the parts with a great progress is called charge array load. The strength, plasticity and Angle discussed behind the square pipe charge array toughness under the action of metal charge array load are all machine function gauges under the action of static load of Q215 welded square pipe. In practice, many machines are under repeated load employment, under this environment the whole opportunity to fatigue. Fatigue Angle is to weigh the metal data soft and hard level of the needle. The most rare method of internal Angle fixing in the current life is the pressure Angle method, which is to use a certain number of what shape of the pressure head is under a certain load is pressed into the tested Q215 welded square tube data surface, according to the pressure into the level to determine the Angle value. The few methods used are HB, HRA, HRB, HRC and HV. Angular plasticity refers to the power of metal data under load, plastic deformation (permanent deformation) without damage. Plastic Q215 welded square tube non-standard seamless square tube is a seamless round tube extrusion molding. The seamless tube and weld points means, it is a square head tube type (torque tube), the spirit of the many kinds of materials are able to constitute a party pipe (square torque tube), it is medium from, why, what use is the central, large minority Q215 welded square tube steel tube as a minority, for square tube structure, whitewash square tube, architects pipe (square torque tube), etc. Square tube Introduction Square tube functions.

Chemical Composition

S460N material

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 | max 0.6 | 1 – 1.7 | max 0.8 | max 0.03 | max 0.025 | max 0.3 | max 0.1 | max 0.2 | max 0.025 | max 0.05 | max 0.05 | max 0.02 | max 0.55 | max 0.55 |

S420N material

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 | max 0.6 | 1 – 1.7 | max 0.8 | max 0.03 | max 0.025 | max 0.3 | max 0.1 | max 0.2 | max 0.025 | max 0.05 | max 0.05 | max 0.02 | max 0.55 | max 0.52 |

S420NL material:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 | max 0.6 | 1 – 1.7 | max 0.8 | max 0.025 | max 0.02 | max 0.3 | max 0.1 | max 0.2 | max 0.025 | max 0.05 | max 0.05 | max 0.02 | max 0.55 | max 0.52 |

S460NL material:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 | max 0.6 | 1 – 1.7 | max 0.8 | max 0.025 | max 0.02 | max 0.3 | max 0.1 | max 0.2 | max 0.025 | max 0.05 | max 0.05 | max 0.02 | max 0.55 | max 0.55 |

Mechanical Properties

S460N material

| Nominal thickness (mm): | to 100 | 100 – 200 |

| Rm - Tensile strength (MPa) | 540-720 | 530-710 |

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 100 | 100 – 150 | 150 – 200 |

| ReH - Minimum yield strength (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV - Impact energy (J) longitud., (+N) | +20° 55 |

0° 47 |

-10° 43 |

-20° 40 |

|

| KV - Impact energy (J) transverse, (+N) | +20° 31 |

0° 27 |

-10° 24 |

-20° 20 |

|

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 200 |

| A - Min. elongation Lo = 5,65 √ So (%) | 17 | 17 | 17 | 17 | 17 |

S420N material:

| Nominal thickness (mm): | to 100 | 100 – 200 | 200 – 250 |

| Rm - Tensile strength (MPa) | 520-680 | 500-650 | 500-650 |

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 100 | 100 – 150 | 150 – 200 | 200 – 250 |

| ReH - Minimum yield strength (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV - Impact energy (J) longitud., (+N) | +20° 55 |

0° 47 |

-10° 43 |

-20° 40 |

|

| KV - Impact energy (J) transverse, (+N) | +20° 31 |

0° 27 |

-10° 24 |

-20° 20 |

|

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 200 | 200 – 250 |

| A - Min. elongation Lo = 5,65 √ So (%) | 19 | 19 | 19 | 18 | 18 | 18 |

S420NL material:

| Nominal thickness (mm): | to 100 | 100 – 200 | 200 – 250 |

| Rm - Tensile strength (MPa) | 520-680 | 500-650 | 500-650 |

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 100 | 100 – 150 | 150 – 200 | 200 – 250 |

| ReH - Minimum yield strength (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV - Impact energy (J) longitud., (+N) | +20° 63 |

0° 55 |

-10° 51 |

-20° 47 |

-30° 40 |

-40° 31 |

-50° 27 |

|

| KV - Impact energy (J) transverse, (+N) | +20° 40 |

0° 34 |

-10° 30 |

-20° 27 |

-30° 23 |

-40° 20 |

-50° 16 |

|

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 200 | 200 – 250 |

| A - Min. elongation Lo = 5,65 √ So (%) | 19 | 19 | 19 | 18 | 18 | 18 |

S460NL material:

| Nominal thickness (mm): | to 100 | 100 – 200 |

| Rm - Tensile strength (MPa) | 540-720 | 530-710 |

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 100 | 100 – 150 | 150 – 200 |

| ReH - Minimum yield strength (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV - Impact energy (J) longitud., (+N) | +20° 63 |

0° 55 |

-10° 51 |

-20° 47 |

-30° 40 |

-40° 31 |

-50° 27 |

|

| KV - Impact energy (J) transverse, (+N) | +20° 40 |

0° 34 |

-10° 30 |

-20° 27 |

-30° 23 |

-40° 20 |

-50° 16 |

|

| Nominal thickness (mm): | to 16 | 16 – 40 | 40 – 63 | 63 – 80 | 80 – 200 |

| A - Min. elongation Lo = 5,65 √ So (%) | 17 | 17 | 17 | 17 | 17 |

Product Display

Product detail pictures:

Related Product Guide:

To get the stage of realizing dreams of our employees! To build a happier, more united and much more skilled crew! To reach a mutual benefit of our prospects, suppliers, the society and ourselves for Factory Free sample Black Steel Square Tube - Square Structural Steel Tubing – Zheyi , The product will supply to all over the world, such as: Kyrgyzstan, Lebanon, South Korea, With the effort to keep pace with world's trend, we will always endeavor to meet customers' demands. If you want develop any other new products, we can customize them for you. If you feel interest in any of our products or want develop new products, please feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.