EN 10219-1 Structural Hollow Sections

EN 10219-1 Specification is for Cold-formed Welded Structural Hollow Sections of Non-alloy and Fine Grain Steels

Cold forming

Cold-formed hollow sections are manufactured through the continuous forming at room temperature of a steel strip passing through forming stands that progressively bend it into a circular shape. This circular shape then enters a welding stand that joins the strip edges together in a continuous longitudinal weld seam. After the welding station, the outside seam of the circular tube is removed, and the final shape (Circular, Square, Rectangular) and precise dimensions of the tube are achieved by passing it through sizing stands.

A cutting saw then divides the length of the welded tube into standard or customised lengths as required.

Weld seams are ensured via electromagnetic NDT inspection.

These products meet all of the EN 10219-1 standard requirements.

Garde:S235JRH,S275J0H,S275J2H,S355J0H,S355J2H,S355K2H

Type: Cold-fromed (ERW)

Circular Hollow Section:

OD: 21.3-1219mm WT: 2-30mm

Square Hollow Section:

OD: 20 X 20 - 400 X 400mm WT: 2-40mm

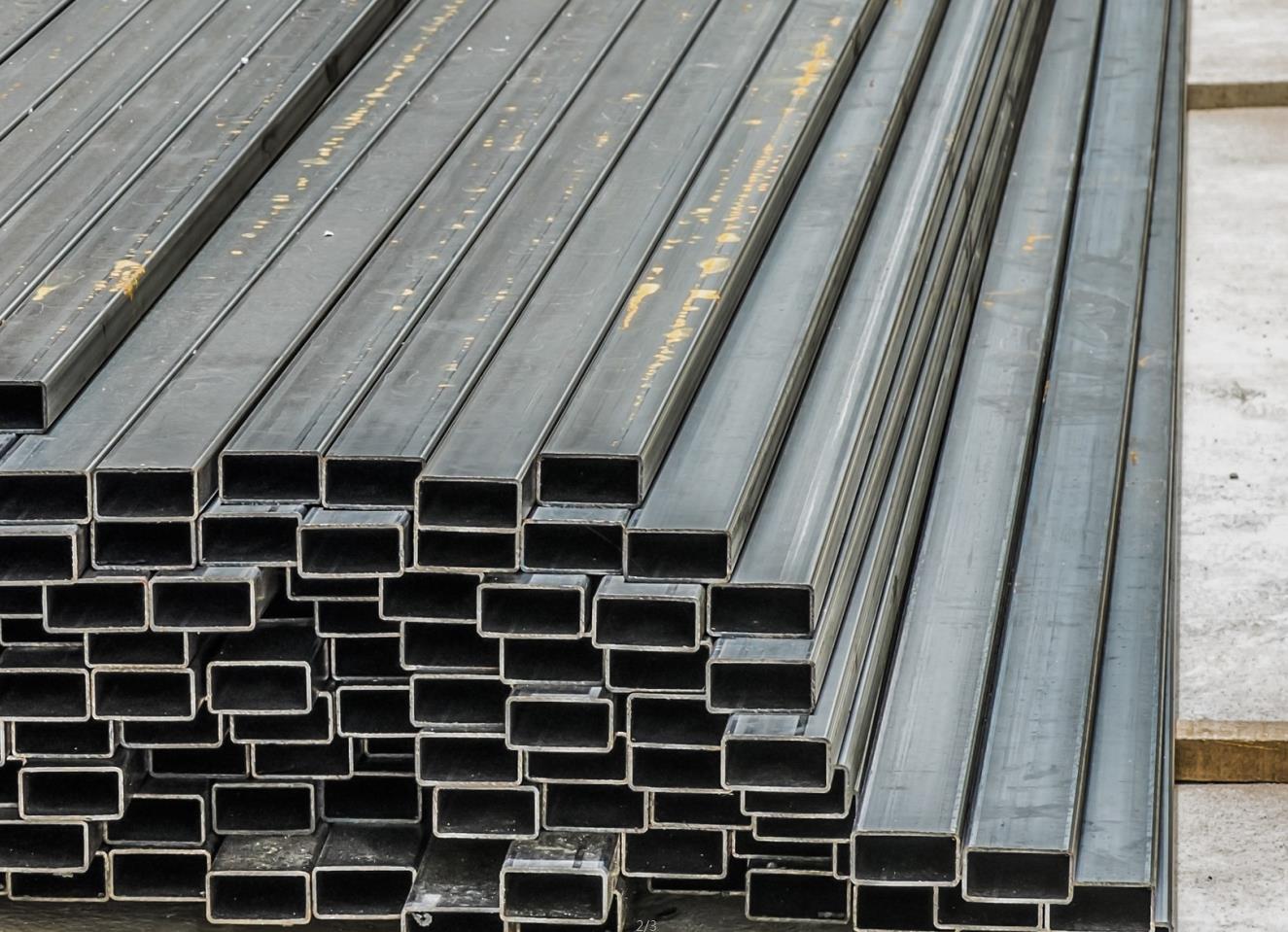

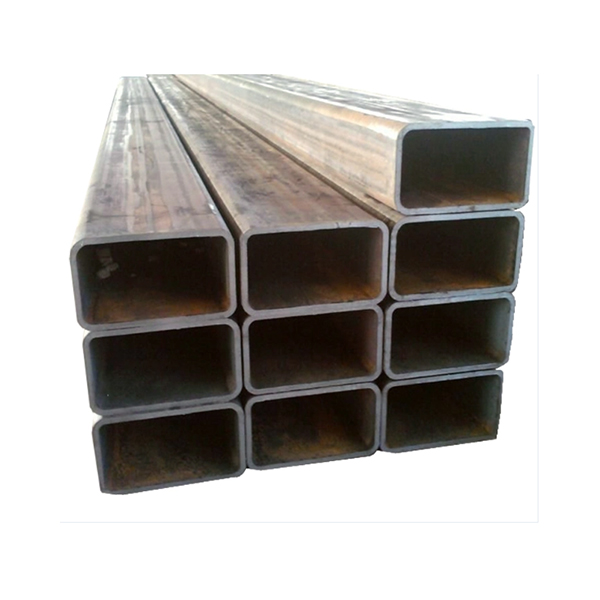

Rectangular Hollow Section:

OD: 40 X 20 - 400 X 300mm WT: 2-16mm

EN 10219-1 S235/S275/S355 Chemical Analysis:

| Steel grade | Type of de-oxidation a | % by mass, maximum | ||||||

| Steel name | Steel number | C | C | Si | Mn | P | S | Nb |

| S235JRH | 1.0039 | FF | 0,17 | — | 1,40 | 0,040 | 0,040 | 0.009 |

| S275J0H | 1.0149 | FF | 0,20 | — | 1,50 | 0,035 | 0,035 | 0,009 |

| S275J2H | 1.0138 | FF | 0,20 | — | 1,50 | 0,030 | 0,030 | — |

| S355J0H | 1.0547 | FF | 0,22 | 0,55 | 1,60 | 0,035 | 0,035 | 0,009 |

| S355J2H | 1.0576 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| S355K2H | 1.0512 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| a. The deoxidation method is designated as follows:

FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al). b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. |

||||||||

Application:

- Bridges

- Railway Station Hall Roofs

- Airport Waiting Hall Roofs

- Trusses

- Bus Shelters

- Library Roofs