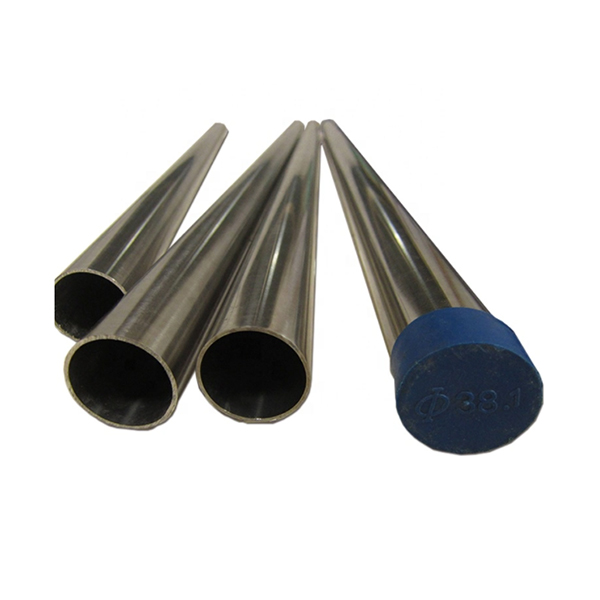

Carbon seamless steel tubes oil and gas ERW carbon steel tubes

carbon seamless steel pipe, It's a long strip of steel. The steel pipe has a hollow section and is widely used for conveying fluid pipelines, such as conveying oil, natural gas, gas, water and some solid materials. Compared with solid steel such as round steel, steel pipe has the same bending and torsional strength and lighter weight. It is a kind of economic cross-section steel, widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipe, automobile drive shaft, bicycle frame and steel scaffolding used in construction.

Making ring parts with steel pipe can improve material utilization rate, simplify manufacturing process, save material and processing time, such as rolling bearing ring, jack sleeve, etc., steel pipe has been widely used to manufacture.

Steel pipe or all kinds of conventional weapons indispensable material, gun barrel, barrel and so on to make steel pipe. Steel pipe can be divided into round pipe and special-shaped pipe according to the shape of cross-sectional area. Since the volume of a circular surface is maximum with equal perimeters, more fluid can be transported with a circular tube. In addition, the annular section under internal or external radial pressure, the force is more uniform, so the vast majority of steel tubes are round.

Manufacturing ring parts with steel pipe can improve material utilization rate, simplify manufacturing process, save material and processing time, such as rolling bearing ring, jack sleeve, etc., has been widely used to manufacture steel pipe.

Carbon Seamless Steel Pipe, Material Factors

(1) carbon seamless steel pipe,the importance of structure heavy industrial building structure, large span structure, high-rise or super high-rise civil building structure or structures and other important structures, should consider the use of good quality seamless steel pipe, for general industrial and civil building structure, according to the nature of the work, the use of ordinary quality seamless steel pipe.

(2) carbon seamless steel pipe,The structure bearing dynamic load directly and the structure in strong earthquake area should choose seamless steel pipe with good comprehensive performance; Generally under static load structure can choose the lower price of seamless steel pipe.

(3) carbon seamless steel pipe, Connection method The welding process will produce welding deformation, welding stress and other welding defects, which may lead to cracks or brittle fracture of the structure. Therefore, welding structure should be strict to material requirements.

(4) carbon seamless steel pipe,The temperature and environment of the structure, seamless steel pipe is easy to be cold and brittle at low temperature, so the structure working at low temperature, especially the welding structure, should choose the killed steel with good low temperature brittle fracture resistance. In addition, the open air structure of Taiyuan seamless steel pipe is easy to produce aging, harmful medium effect of seamless steel pipe is easy to corrosion, fatigue and fracture, should also be different to choose different materials.

(5) too seamless steel pipe thickness, thin seamless steel pipe rolling times, rolling compression ratio is large, large thickness of seamless steel pipe compression ratio is small, so the thickness of precision steel pipe is not only small strength, but also poor plasticity, impact toughness and welding performance. Therefore, the welded structure with large thickness should use better seamless steel pipe.

Carbon Seamless Steel Pipe, There Are Several Criteria

GB8163 "Seamless steel pipe for fluid Transportation",

GB6479 "High pressure seamless steel pipe for fertilizer equipment",

GB9948 "Seamless steel pipe for Petroleum Cracking",

GB3087 "Seamless steel tubes for Low and medium pressure boilers",

GB5310 "Seamless steel tube for high pressure boiler".

Specification

| Executive Standard | Grade / Material | Product Name |

| ASTM A53 | A, B | Black and Hot-Dipped Zinc-Coated Steel Pipes Welded and Seamless |

| ASTM A106 | A, B | Seamless Carbon Steel for High Temperature Service |

| ASTM A179 | Low Carbon Steel | Seamless Cold-Drawn Low-Carbon Steel Heat Exchanger and Condenser Tubes |

| ASTM A192 | Low Carbon Steel | Seamless Carbon Steel Boiler Tubes for High Pressure |

| ASTM A210 | A1, C | Seamless Medium-Carbon and Alloy Steel Boiler and Super heater Tubes |

| ASTM A213 | T5, T11, T12, T22 TP 347H |

Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat- Exchanger Tubes |

| ASTM A312 | TP304/304L, TP316/316L | Seamless Steel Pipe for Stainless Materials |

| ASTM A333 | Gr.6 | Seamless and Welded Steel Pipe for Low-Temperature Service |

| ASTM A335 | P9, P11, P22 | Seamless Ferritic Alloy Steel Pipe for High-Temperature Service |

| ASTM A519 | 4130,4140 | Seamless Carbon and Alloy Steel for Mechanical Tubing |

| ASTM A789 | Seamless Ferritic/Austenitic Stainless Steel Tubing for General Service |

Api Standard For Seamless Steel Pipe

| Executive Standard | Grade / Material | Product Name |

| API Spec 5CT | J55, K55, N80, L80,C90, C95, T95, P110, M65 | Specification for Casing and Tubing |

| API Spec 5L PSL1 / PSL2 | A,B X42, X46, X52, X56, X60, X65,. X70 | Specification for Line Pipe |

EN/DIN Standard For Seamless Steel Pipe

| Executive Standard | Grade / Material | Product Name |

| DN 17175/EN10216-2 | ST35, ST45, ST52, 13CrMo44 | Seamless Steel Tube for Elevated Temperature |

| DIN 2391/EN10305-1 | St35, St45, St52 | Cold Drawn Seamless Precision Pipe |

| DIN 1629/EN10216-1 | St37, St45, St52 | Seamless Circular unalloyed Steel Tubes Subject to Special Requirements |

EN/DIN Standard For Seamless Steel Pipe

| Product | Seamless Steel Pipe For Exploration & Production |

| OD | 13.72 mm - 914.4 mm |

| WT | 1.65 mm - 22 mm |

| Length | 0.5 m - 20 m |

| Standard | API 5L PSL1 /PSL2 |

| Material | GR.B/X42/46/X52/56/X60/65/X70/80 |

| Usage | Chilled Water Pipe, Drinking water Pipe, W aste Water Pipe, Structural Tube, Fluid Pipe, Boiler Pipe, Oil and Gas Transportation Pipe, Mechanical Structure Pipe |

Parameters

| Product | Seamless Steel Pipe For Exploration & Production |

| OD | 13.72 mm - 914.4 mm |

| WT | 1.65 mm - 22 mm |

| Length | 0.5 m - 20 m |

| Standard | API 5L PSL1 /PSL2 |

| Material | GR.B/X42/46/X52/56/X60/65/X70/80 |

| Usage | Chilled Water Pipe, Drinking water Pipe, W aste Water Pipe, Structural Tube, Fluid Pipe, Boiler Pipe, Oil and Gas Transportation Pipe, Mechanical Structure Pipe |

Chemical Composition And Mechanical Properties

| API 5L PSL1 | |||||||

| Standard | Grade | Chemical Components | Tensile STrength(min) | Yield Strength(min) | |||

| C | Mn | P | S | Mpa | Mpa | ||

| API 5L | A | 0.22 | 0.90 | 0.030 | 0.030 | 331 | 207 |

| PSL1 | B | 0.28 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 414 | 290 | |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 434 | 317 | |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 455 | 359 | |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 490 | 386 | |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 517 | 414 | |

| X65 | 0.28 | 1.40 | 0.030 | 0.030 | 531 | 448 | |

| X70 | 0.28 | 1.40 | 0.030 | 0.030 | 565 | 483 | |

| API 5L PSL2 | |||||||

| Standard | Grade | Chemical Components | Tensile STrength(min) | Yield Strength(min) | |||

| C | Mn | P | S | Mpa | Mpa | ||

| API 5L | B | 0.24 | 1.20 | 0.025 | 0.015 | 414 | 241 |

| PSL2 | X42 | 0.24 | 1.30 | 0.025 | 0.015 | 414 | 290 |

| X46 | 0.24 | 1.40 | 0.025 | 0.015 | 434 | 317 | |

| X52 | 0.24 | 1.40 | 0.025 | 0.015 | 455 | 359 | |

| X56 | 0.24 | 1.40 | 0.025 | 0.015 | 490 | 386 | |

| X60 | 0.24 | 1.40 | 0.025 | 0.015 | 517 | 414 | |

| X65 | 0.24 | 1.40 | 0.025 | 0.015 | 531 | 448 | |

| X70 | 0.24 | 1.40 | 0.025 | 0.015 | 565 | 483 | |

| X80 | 0.24 | 1.40 | 0.025 | 0.015 | 621 | 552 | |

Types Of Galvanized Steel Pipe

| STANDARDS | PRODUCTS | RANGES |

| IS:1239 (Part-I) | Mild Steel Tubes, Tubular | 15mm NB - 150mm NB |

| IS:1161 | Mild Steel Tubes for Structural purpose | 15mm NB - 200mm NB |

| IS:3601 | Mild Steel tubes for Mechanical & General Eng. purpose | 20mm x 0.80mm to 165.10 x 7.00 mm |

| IS:3589 | ERW Pipes for water Gas & Sewage | 168.3 x 4.00 mm to 219.1 x 7.00mm |

| IS:9295 | Steel Tubes for Idlers for Belt conveyors | 63.5 x 4.00 mm to 219.1 x 7.0 mm |

| IS:4270 | Steel Tubes for Water Wells | 114.3 x 5.00mm to 219.1mm x 7.1mm |

| IS:7138 | Steel Tubes for furniture | 20.0 x .60mm to 60.0 x 2.0mm |

| IS:4923 | Hollow Steel sections for structural purpose | 12.5 x 12.5 x 0.80 to 150 x 150 x 6.0mm 10 x 20 x 0.80mm to 150 x 200 x 6.0mm |

| IS:3074 | Steel Tubes for Automobile purpose | 19.7 x 1.00mm to 101.6 x 6.0mm |

| BS:1387 | Screwed & Socket Steel Tubes & Tubular | ½"NB to 6″NB 2.00 mm - 5.40 mm wall thick |

| BS:3601 | Steel Pipes & Tubes for pressure purpose | ½"NB to 6″NB 2.00 mm - 7.00 mm wall thickness |

| BS:6323 | Steel tubes for mechanical & general engineering purposes | 21.3″ to 219.1mm OD wall thickness-1.60-7.00 mm |

Product Display