Bottom price Fire Coated Plastic Pipe - Plastic coated inside and outside composite pipe – Zheyi

Bottom price Fire Coated Plastic Pipe - Plastic coated inside and outside composite pipe – Zheyi Detail:

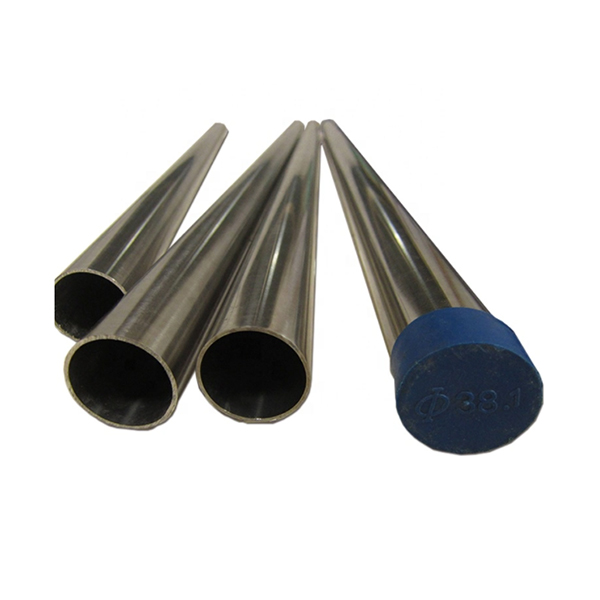

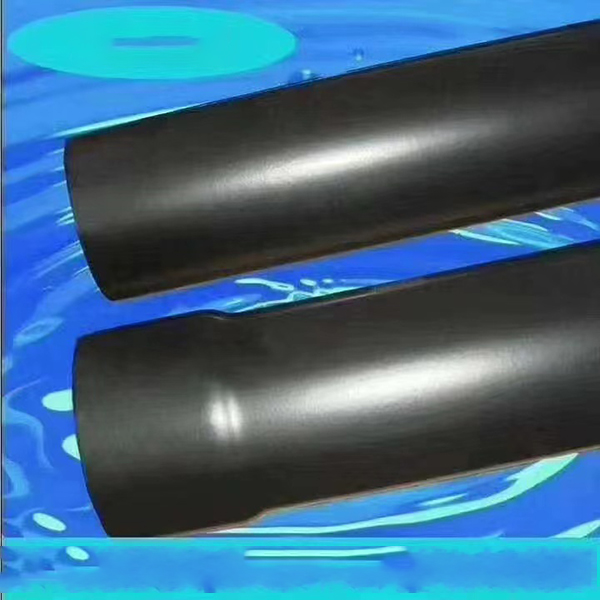

Plastic coated inside and outside composite pipe, The inner and outer coated plastic composite pipe is a kind of steel plastic composite pipe composed of a layer of 0.5 ~ 1.0mm polyethylene (PE) resin, ethylene-acrylic acid copolymer (EAA), epoxy (EP) powder, non-toxic polypropylene (PP) or non-toxic polyvinyl chloride (PVC) and other organic matters dissolved in the inner wall of the pipe.

Plastic coated inside and outside composite pipe, It not only has the advantages of high strength steel pipe, easy connection, water impact resistance, but also overcome the steel pipe water corrosion, pollution, scaling and plastic pipe strength is not high, poor fire performance and other shortcomings, design life up to 50 years. The main disadvantage is that the installation shall not be bent, hot working and welding and cutting operations, cutting surface application manufacturers equipped with non-toxic normal temperature curing adhesive coating. The main specifications are φ 15 – φ 100.

Plastic coated inside and outside composite pipe, Main models are divided into: GS – - X – SP – T – EP, GS – - SP – T – EP, GS – - D – SP – T – EP (PE)

Plastic Coated Inside And Outside Composite Pipe, Standard

Steel pipe with reference to national standard: GB/T3091-2001; Industry standard of plastic-coated composite steel pipe: CJ/T120-2008; Industry standard of plastic lined composite steel pipe: CJ/T136-2007; Thermal conductivity: 65 W/(m.K); Linear expansion coefficient: 65 1/K; Steel-plastic composite pipe: GB/T 28897-2012;

Plastic Coated Inside And Outside Composite Pipe, Product Advantages

With high mechanical strength, suitable for harsh environment;

The inner and outer coating can prevent metal oxidation and has good chemical corrosion resistance.

The coating has strong adhesion, high bonding strength and good impact resistance.

Low roughness coefficient and friction coefficient, excellent resistance to foreign body adhesion;

Anti aging, long service life, especially suitable for buried water delivery.

Plastic Coated Inside And Outside Composite Pipe, Inspection Methods

A visual inspection

Visually inspect the appearance quality of the coated steel pipe, and the test results shall comply with the provisions of 5.1.

Thickness measurement

Two cross sections of different lengths are taken from both ends of the coated steel pipe. In each cross section, the coating thickness at any four points directly intersecting the circumference is measured with the electromagnetic thickness gauge. The test results shall conform to the provisions of 5.4.

Pinhole test

The length of the pipe section specimen is about 1000 mm. The coating of the steel tube is inspected by the spark leak detector under the specified test voltage. The coating thickness is less than 0.4mm, the test voltage is 1500 V, the coating thickness is more than 0.4mm, and the test voltage is 2000 V. Check whether electric spark is generated and test result should conform to 5.5.

Adhesion test

The adhesion test shall be carried out according to 7.4.2 of CJ/T 120-2008, and the test results shall conform to 5.6.

Bending test

Bend test for coated steel pipe DN≤50mm. The length of the pipe section specimen is (1200±100) mm.

At the temperature of (20±5) ℃, 8 times of the nominal diameter of the steel pipe as the radius of curvature, bending Angle of 30O, bending on the pipe bender or die. When bending test, there is no filler in the tube, and the weld is located on the side of the main bending surface.

After the test, cut the specimen from the middle of the curved arc to check the inner coating, and the test results should comply with the provisions of 5.7.

Flattening test

DN> The 50 mm coated steel tube shall be compressed. The length of pipe section specimen is (50±10) mm.

The specimen was placed between two plates at the temperature of (20±5) ℃, and was gradually compressed on the pressure test machine until the distance between the two plates was four-fifths of the outer diameter of the specimen. The welded seam of the coated steel pipe was perpendicular to the direction of load application. After the test, the inner coating shall be checked and the test results shall conform to 5.8.

Impact test

A sample about 100 mm in length was cut from any position of the coated steel pipe, and the impact test was carried out according to the provisions in Table 2 at the temperature of (20±5) ℃ to observe the damage of the inner coating. During the test, the weld shall be in the opposite direction of the impact surface, and the test result shall comply with the provisions of 5.9.

Table 2 Impact test conditions

Nominal diameter DN

Mm hammer weight, kg falling height, mm

15-251.0300

32 ~ 502.1500

80 ~ 3006.31000

Impact test apparatus

Vacuum test

The length of the pipe section specimen is (500±50) mm. Use appropriate measures to block the inlet and outlet of the pipe, and gradually increase the negative pressure from the inlet to 660 mm hg, keep it for 1 min. After the test, check the inner coating, and the test results should comply with the provisions of 5.10.

High temperature test

The length of the pipe section specimen was (100±10) mm. The specimen was placed in the incubator and heated to (300±5) ℃ for 1 h. Then it was removed and cooled naturally to normal temperature. After the test, take out the specimen and check the inner coating (darker and darker appearance is allowed), and the test results should comply with 5.11.

Low temperature test

The pipe section specimen was of (100±10) mm in size and length. The specimen was placed in a cryogenic chamber, cooled to (-30±2) ℃ and kept at a constant temperature for 1 h. Then it was removed and placed at a temperature of (20±5) ℃ for (4-7) h. At the end of the test period, the specimen shall be taken out to check the inner coating, and the adhesion test shall be carried out according to the provisions of 6.4, and the test results shall conform to the provisions of 5.12.

Pressure cycle test

The length of the pipe section specimen was (500±50) mm. Appropriate measures were used to block the inlet and outlet of the pipe, and the pipe was connected with the water supply system. Water was filled to remove air, and then 3000 alternating hydrostatic tests from (0.4±0.1) MPa to MPa were carried out, and the period of each test was not more than 2 s. After the test, the inner coating shall be checked and the adhesion test shall be carried out according to the provisions of 6.4, and the test results shall conform to the provisions of 5.13.

Temperature cycle test

The length of the pipe section specimen was (500±50) mm. The specimens were placed for 24 h at each temperature in the following order:

(50±2) ℃;

(-10±2) ℃;

(50±2) ℃;

(-10±2) ℃;

(50±2) ℃;

(-10±2) ℃.

After the test, the specimen was placed in an environment with a temperature of (20±5) ℃ for 24 h. The inner coating was checked and the adhesion test was carried out according to the provisions of 6.4. The test results should conform to the provisions of 5.14.

Warm water aging test

The size and length of the pipe section specimen is about 100 mm. The exposed parts at both ends of the pipe section should be treated with anticorrosion. The pipe section should be soaked in distilled water at (70±2) ℃ for 30 days.

Specification

| Item | Plastic coated inside and outside composite pipe |

| Material | SPHC, Q195,Q215,Q235,Q345,SAE1010,SAE1020, API Standard material, ASTM A53 A,B |

| OD | 10-1219(1/8”-48”) |

| WT | 0.7-13 |

| Length | 2m-12m or as per customers’ requirement |

| Thickness Tolerance | + 5%- |

| Surface | oiled/painted |

| Pipe end | Plain end/Beveled end/Thread with coupling and cap |

| Marking | As per customer’s requirement |

| Sdandard | ASTM/BS EN/DIN/GB |

| Certificate | ISO,BV,API |

| ODM/OEM | available |

| Standards | ASTM A53,BS1387-1985,GB/T3091-2001,GB/T13793-92, GB/T6728-2002 |

| Materials | Q195,Q215,Q235,Q345 |

| Technique | Welded |

| Usage | Mechanical & manufacture, Steel structure, Shipbuilding, Bridging ,Automobile chassis |

Constituent Of The Material

| Grade | C | Mn | Si | S | P | UTS(MPa) | YS(MPa) | EI(%) |

| Q235B | 0.12-0.20 | 0.30-0.70 | 0.30 | 0.045 | 0.045 | 375-500 | 235 | 26 |

| Q345B | 0.12-0.20 | 1.20-1.60 | 0.20-0.55 | ≤0.045 | ≤0.045 | 510-600 | 345 | 22 |

| 20#(GB) | 0.17-0.23 | 0.38-0.65 | 0.17-0.37 | ≤0.030 | ≤0.030 | 410-550 | ≥245 | ≥20 |

| HDPE PIPE SIZES CHART | |||||||||

| Dia | Deviation | 0.4Mpa | 0.5Mpa | 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6MPa | 2.0Mpa |

| Thickness | Thickness | Thickness | Thickness | Thickness | Thickness | Thickness | Thickness | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 16 | 0.3 | 2.3 | |||||||

| 20 | 0.3 | 2.3 | 2.3 | ||||||

| 25 | 0.3 | 2.3 | 2.3 | 3 | |||||

| 32 | 0.3 | 2.3 | 2.4 | 3 | 3.6 | ||||

| 40 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.5 | |||

| 50 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | ||

| 63 | 0.4 | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | ||

| 75 | 0.5 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | ||

| 90 | 0.6 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | ||

| 110 | 0.7 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | ||

| 125 | 0.8 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | ||

| 140 | 0.9 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | ||

| 160 | 1 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | ||

| 180 | 1.1 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | ||

| 200 | 1.2 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | ||

| 225 | 1.4 | 8.6 | 10.8 | 13.4 | 16.6 | 16.6 | 25.2 | ||

| 250 | 1.5 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | ||

| 280 | 1.7 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | ||

| 315 | 1.9 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 |

| 355 | 2.2 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| 400 | 2.4 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| 450 | 2.7 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| 500 | 3 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| 560 | 3.4 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| 630 | 3.8 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 |

| 710 | 6.4 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 |

| 800 | 7.2 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 |

| 900 | 8.1 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |

| 1000 | 9 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |

Product Display

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Bottom price Fire Coated Plastic Pipe - Plastic coated inside and outside composite pipe – Zheyi , The product will supply to all over the world, such as: Ireland, Montpellier, Slovakia, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.