Best quality Hollow Structural Section - ASTM A500 square steel pipe factory supplier spot – Zheyi

Best quality Hollow Structural Section - ASTM A500 square steel pipe factory supplier spot – Zheyi Detail:

A500 Carbon Steel Square Tubing, large diameter square steel pipe, seamless square steel pipe, low alloy square steel pipe, 135*135*10 square steel pipe, tower crane square steel pipe, Q345B low alloy square steel pipe, 20# seamless square steel pipe

A500 Carbon Steel Square Tubing, as the name implies, it is a square shape of the tube, many kinds of material can form a square tube body, its medium in, what to use, where to use, most of the square pipe to steel pipe for the majority, mostly for structural square pipe, decoration square pipe, building square pipe and so on.

Square pipe is a name for square pipe, that is, steel pipe with equal length on both sides. It is made of strip steel after processing and rolling. Generally, the strip is unpacked, leveled, crimped and welded into a round tube, which is rolled into a square tube and then cut into the required length. Usually 50 sticks per pack.

Classification And Performance

The seamless A500 Carbon Steel Square Tubing is divided into seamless and weld, seamless square pipe is made of seamless round tube extrusion. Square steel pipe, thick wall square steel pipe, large diameter square steel pipe, seamless square steel pipe, low alloy square steel pipe, 135*135*10 square steel pipe, tower crane square steel pipe, Q345B low alloy square steel pipe, 20# seamless square steel pipe

1. Performance index analysis of square steel tube – plasticity

Plasticity refers to the ability of a metal material to produce plastic deformation (permanent deformation) without damage under load.

2. Performance index analysis of square steel tube – hardness

Hardness is a gauge of how hard or soft a metal material is. At present, the most commonly used method to determine hardness in production is the indenter hardness method, which is to use a certain geometric shape of the indenter head under a certain load into the surface of the tested metal materials, according to the degree of the indenter to determine its hardness value.

Commonly used methods are Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV) and other methods.

3. Performance index analysis of square steel tube – fatigue

The strength, plasticity, and hardness discussed above are indicators of the mechanical properties of metals under static loading. In fact, many machine parts are operated under cyclic loads, and fatigue can occur under these conditions.

4. Performance index analysis of square steel pipe – impact toughness

The load acting on the parts at a high speed is called impact load, and the ability of metal to resist damage under impact load is called impact toughness.

5. Performance index analysis of square steel tube – strength square steel tube, thick wall square steel tube, large diameter square steel tube, seamless square steel tube, low alloy square steel tube, 135*135*10 square steel tube, tower crane square steel tube, Q345B low alloy square steel tube, 20# seamless square steel tube

Strength is the ability of a metal material to resist failure (excessive plastic deformation or fracture) under static loading. Due to the mode of loading in the form of stretching, compression, bending, shearing, so the strength is also divided into tensile strength, compressive strength, bending strength, shear strength and so on. There is often a certain connection between various strengths, and tensile strength is generally used as the most basic strength pointer.

End shape: oblique end, flat end, disappear or add plastic cover to protect ends according to customer’s requirements Oiled, galvanized, painted black

Technology: hot rolling, cold rolling

A500 Carbon Steel Square Tubing Application

1. Structural applications, industrial and residential construction

2. Fence post/fence/bollards/bed frame

3. The gas

4. In fire sprinkler system/water supply

5. Sports equipment/light pole/lamp post

6. Agriculture/greenhouse

Specification

| Resistance welding | |||||||||

| thing | Maximum chemical composition % | thing | Mechanical behavior | ||||||

| steel | C % | Manganese % | % | % | silicon% | steel | Yield point Mpa | Tensile strength Mpa | Elongation |

| Class A | 0.25 | 0.95 | 0.045 | 0.05 | – | Class A | 205 (minutes) | 330 (minutes) | 26-30 |

| Class B | 0.3 | 1.2 | 0.045 | 0.05 | – | Class B | 240 (minutes) | 415 (minutes) | 21-26 |

| Quality Standards: ASTM A53 ASTM A500 Standard Specification for Pipe, Black and Hot Dip, Galvanized, Welded, and Seamless Tubing | |||||||||

Chemical Composition

| Chemical requirements | Mechanical behavior | Special-shaped structure tube | |||||||||

| Element | work. % | Class A | Class B | Class C | Class D | ||||||

| Class A, B, D | Class C | Tensile strength, min, | psi | 45000 | 58000 | 62000 | 58000 | ||||

| Thermal Analysis |

Product Analysis |

Thermal Analysis |

Product Analysis |

MPa | 310 | 400 | 427 | 400 | |||

| Yield Strength, Min, | psi | 33000 | 42000 | 46000 | 36000 | ||||||

| C, maximum | 0.26 | 0.30 | 0.23 | 0.27 | MPa | 228 | 290 | 317 | 250 | ||

| Manganese, max | … | … | 1.35 | 1.40 | 2″ elongation. (50.8mm), min % | 25 | twenty three | twenty one | twenty three | ||

| P, max | 0.035 | 0.045 | 0.035 | 0.045 | Quality Standard: ASTM A500 Standard Specification for Round and Shaped Cold-Formed Welded and Seamless Carbon Steel Structural Pipe | ||||||

| small, largest | 0.035 | 0.045 | 0.035 | 0.045 | |||||||

| Copper, (when specified) min. | 0.20 | 0.18 | 0.20 | 0.18 | |||||||

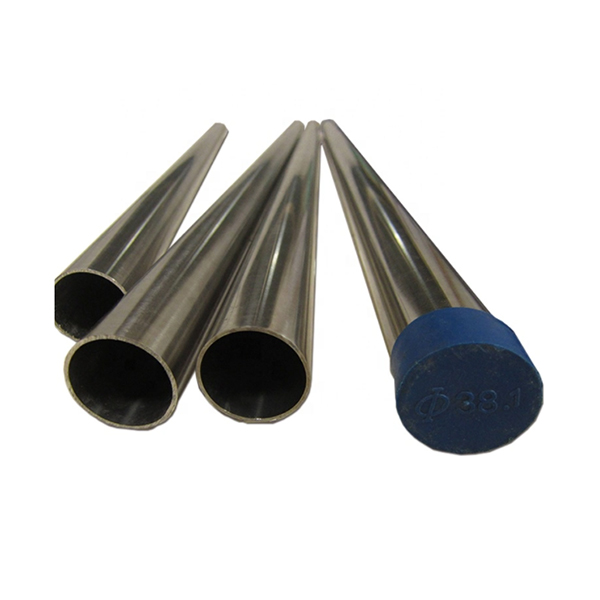

Product Display

Product detail pictures:

Related Product Guide:

Being supported by an advanced and professional IT team, we could offer technical support on pre-sales & after-sales service for Best quality Hollow Structural Section - ASTM A500 square steel pipe factory supplier spot – Zheyi , The product will supply to all over the world, such as: Stuttgart, kazan, Myanmar, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.