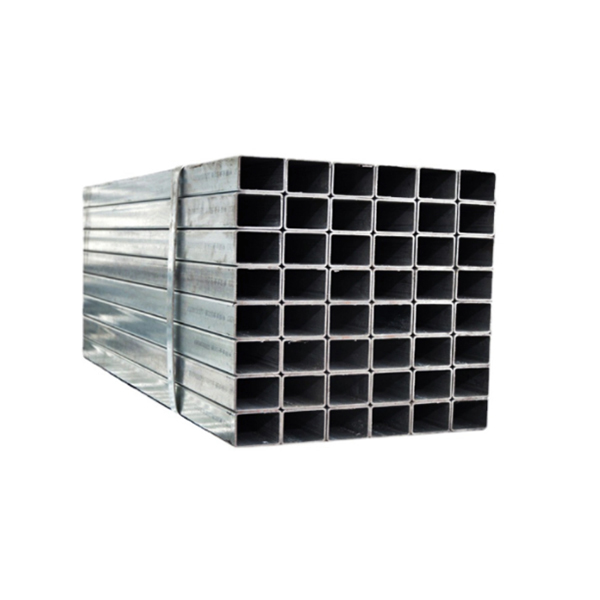

304 stainless steel pipe

Product usage

304 stainless steel is the most widely used chromium-nickel stainless steel. As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; good hot workability such as stamping and bending, no heat treatment Hardening phenomenon (use temperature -196℃~800℃). Corrosion resistance in the atmosphere, if it is an industrial atmosphere or heavily polluted area, it needs to be cleaned in time to avoid corrosion. Suitable for food processing, storage and transportation. Has good processability and weldability. Plate heat exchangers, bellows, household products (Class 1 and 2 tableware, cabinets, indoor pipelines, water heaters, boilers, bathtubs), auto parts (windshield wipers, mufflers, molded products), medical appliances, building materials, chemicals, food industry , agriculture, ship parts, etc. 304 stainless steel is a nationally recognized food grade stainless steel.

The characteristics of 304 stainless steel pipe

1. The stainless steel pipe made of 304 is very environmentally friendly, safe and reliable to use.

2. The 304 stainless steel pipe can bend with high Gini performance to a large extent. We know that the construction environment often affects the stainless steel pipe, but the staff will carry out the construction according to the super distortion of the stainless steel pipe.

3. The 304 stainless steel pipe has extremely superior resistance to acid and alkali corrosion. There is a very thin protective film on the outer surface of the stainless steel pipe, but it is very hard. Even if the stainless steel pipe is damaged, as long as there is oxygen around it If it is, then he will regenerate quickly, and there will be no rust.

4. The quality of the 304 stainless steel pipe is very light, so it is convenient to carry and install it, which greatly reduces the cost of the project.

304 stainless steel tube maintenance

1. If the stainless steel pipe fittings are used outdoors, long-term wind and sun exposure will cause stains on the surface of the stainless steel pipe fittings. However, you can wipe the water stains and dirt with a soft towel dipped in water. If they cannot be wiped off, you can use alkaline smear lightly with soap, then wipe gently with a towel.

2. However, do not use steel balls or wire brushes to remove water stains on the surface of stainless steel pipe fittings during the cleaning process, because this will leave traces on the surface of stainless steel pipe fittings, and in this case, it is easy to rust and affect the service life of stainless steel pipe fittings .

3. During the production process, there will be lubricating oil and small steel wires on the surface of the stainless steel welded pipe. Needs to be wiped clean to avoid scratches. During the placement process, it should be placed in a clean and ventilated place.