304 STAINLESS STEEL CAPILLARY TUBING

304 STAINLESS STEEL CAPILLARY TUBING,

,

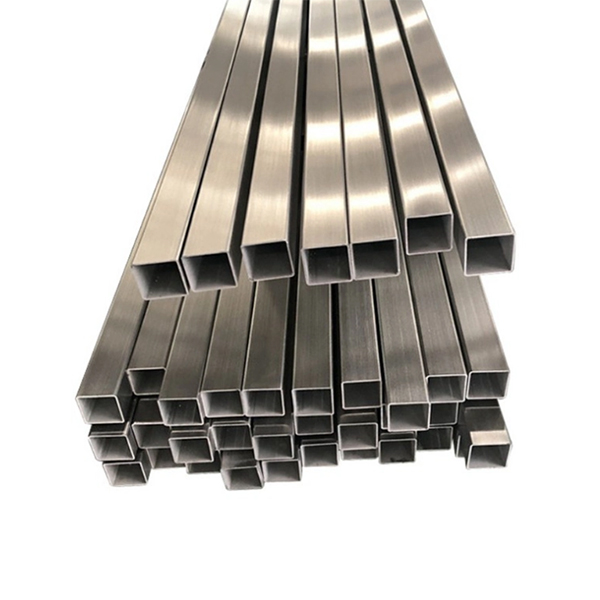

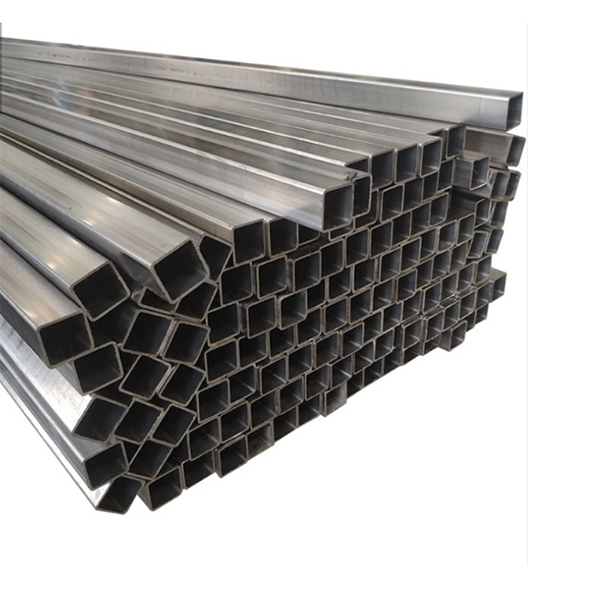

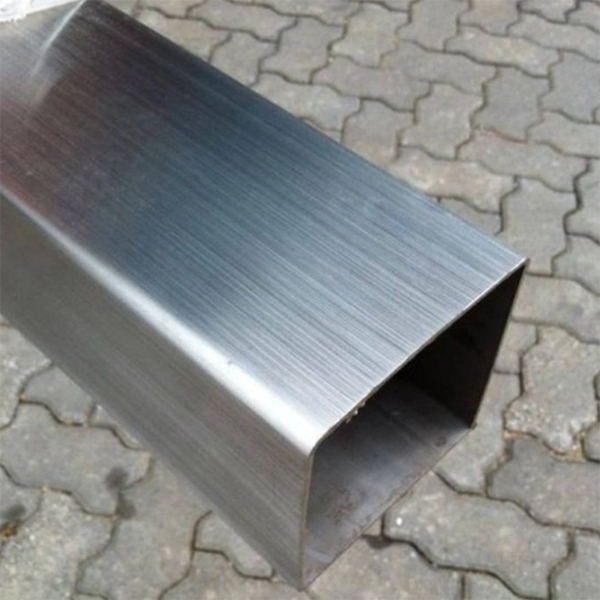

Stainless steel seamless square tubing, It’s a hollow strip of steel called a square pipe because its cross section is square. A large number of pipeline used for conveying fluid, such as oil, natural gas, water, gas, steam, etc., in addition, in bending, torsion strength at the same time, lighter weight, so also widely used in manufacturing machinery parts and engineering structures

Stainless steel square tube classification: square tube is divided into seamless steel tube and welded steel tube (seam pipe) two categories. According to section shape can be divided into square and rectangular tube, widely used is circular steel tube, but there are some semicircular, hexagonal, equilateral triangle, octagonal and other special-shaped steel tube.

For stainless steel square tube under fluid pressure to carry out hydraulic test to test its pressure capacity and quality, under the specified pressure does not leak, wet or expansion for qualified, some steel pipe according to the standard or the requirements of the side of the roll test, flaring test, flattening test.

Square tube specifications: 5*5~150*150 mm thickness :0.4~ 6.0mm

Square tube material: 304, 304L, TP304, TP316L, 316, 316L, 316Ti, 321, 347H, 310S

Stainless Steel Seamless Square Tubing, The Production Process

Round steel preparation → heating → hot rolling perforation → cutting head → pickling → polishing → lubrication → cold rolling process → degreasing → solution heat treatment → straightening → pipe cutting → pickling → finished product inspection.

Stainless Steel Seamless Square Tubing ,Performance Analysis

The metal can react with oxygen in the atmosphere to form an oxide film on the surface. The iron oxide formed on ordinary carbon steel will continue to oxidize, expanding the corrosion and eventually forming holes. This can be done using paint or an oxidation-resistant metal plating to protect the surface of carbon steel, but this coating is only a thin film. If the coating is damaged, the steel underneath begins to rust again. Whether the stainless steel tube is corroded is related to the chromium content in the steel. When the chromium content in the steel reaches 12%, the surface of the stainless steel tube generates a layer of passivation and dense chromium rich oxide to protect the surface and prevent further reoxidation. This oxide layer is extremely thin, through which the natural sheen of the steel surface can be seen, giving stainless steel a unique surface. If the chromium film is damaged once, the chromium in the steel and the oxygen in the atmosphere to regenerate the passivation film, continue to play a protective role. In some special environments, stainless steel will also appear some local corrosion and failure, but stainless steel and carbon steel is different, will not appear uniform corrosion and failure, so the corrosion allowance for stainless steel tube is meaningless.

Specifications

| Product Name | Stainless Steel Seamless Pipe | |

| Steel grade | 300 series | |

| Standard | ASTM A213, A312, ASTM A269, ASTM A778, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 | |

| Material | 304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 304N, 3 16L, 316N, 201, 202 | |

| Surface | Polishing, annealing, pickling, bright | |

| Type | hot rolled and cold rolled | |

| stainless steel round pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8″-100″) | |

| stainless steel square pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 4mm*4mm-800mm*800mm | |

| stainless steel rectangular pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8″-100″) | |

| Length | 4000mm, 5800mm, 6000mm, 12000mm, or as required. | |

| Trade terms | Price terms | FOB, CIF, CFR, CNF, Ex-work |

| Payment terms | T/T, L/C, westen union | |

| Delivery time | Prompt delivery or as the order quantity. | |

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Italy, India, Egypt, Oman, Malaysia, Kuwait, Canada, Viet Nam, Peru, Mexico, Dubai, Russia, etc | |

| Package | Standard export seaworthy package, or as required. | |

| Application | Widely used in petroleum, foodstuff, chemical industry, construction, electric power, nuclear, energy, machinery, biotechnology, paper making, shipbuilding, boiler fields. Pipes also can be made according to the customer’s required. |

|

| Contact | If you have any questions, please feel free to contact me. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

Chemical Composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 – 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 – 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Product Display

Manufacturing range:

stainless steel coil tube

stainless steel tube coil

stainless steel coil tubing

stainless steel coil pipe

stainless steel coil tube suppliers

stainless steel coil tube manufacturers

stainless steel pipe coil

Stainless steel capillary, stainless steel small tube is widely used in medical treatment, fiber-optic, pen making, electronic welding products, light cable joint, food, vintage, dairy, drink, pharmacy and biochemistry, different length can be provided according to requests

Capillary tubes with a maximum bore of 0.0158 in., available in a wide range of stainless steels. Sandvik capillary tubes are characterized by tight tolerances, and the inside surface of the tubes is free from oil, grease and other particles. This ensures, for example, an optimized and even flow of liquids and gases from the sensor to the measuring instrument.

Stainless steel Coiled tubing is available in a range of different product forms depending on the customer requirements. Licancheng sihe stainless steel material manufactures welded and seamless tube products. The standard grades are 304 304L 316L(UNS S31603) Duplex 2205 (UNS S32205 & S31803) Super Duplex 2507 (UNS S32750) Incoloy 825 (UNS N08825) Inconel 625 (UNS N06625) Other grades of stainless steel in duplex and superduplex and nickel alloy are available on request.

Diameter from 3mm (0.118’’) to 25.4mm (1.00’’) OD. Wall thickness from 0.5mm (0.020’’) to 3mm (0.118’’).Tubing can be supplied in the annealed or cold worked stainless steel control line pipe condition.

304 Stainless Steel Chemical Composition

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

304

min.

–

–

–

–

–

18.0

–

8.0

–

max.

0.08

2.0

0.75

0.045

0.030

20.0

10.5

0.10

Stainless Steel 304 Mechanical Properties

Grade

Tensile Strength (MPa) min

Yield Strength 0.2% Proof (MPa) min

Elongation (% in 50mm) min

Hardness

Rockwell B (HR B) max

Brinell (HB) max

304

515

205

40

92

201

Stainless Steel 304 Physical Properties

Grade

Density (kg/m3)

Elastic Modulus (GPa)

Mean Coefficient of Thermal Expansion (m/m/0C)

Thermal Conductivity (W/m.K)

Specific Heat 0-1000C (J/kg.K)

Electrical Resistivity (n.m)

0-1000C

0-3150C

0-5380C

at 1000C

at 5000C

304

8000

193

17.2

17.8

18.4

16.2

21.5

500

720

Electric Properties

Properties

Conditions

T (°C)

Treatment

Electric Resistivity (10-9W-m) 720

25

Stainless Steel 304 Equivalent

Equivalent Grades for 304 Stainless Steel

Grade

UNS No

Old British

Euronorm

Swedish SS

Japanese JIS

GOST

BS

En

No

Name

SS 304

S30400

304S31

58E

1.4301

X5CrNi18-10

2332

SUS 304

08Х18Н10

Specification

Brand Liaocheng Sihe Stainless STEEL

Thickness 0.1-2.0mm

Diameter 0.3-20mm (tolerance: ±0.01mm)

Stainless Grade 201,202,304,304L,316L,317L,321,310s,254mso,904L,2205,625 etc.

Surface Finish inside and outside are both bright annealing, cleaning, and seamless, no leaks.

Standard ASTM A269-2002.JIS G4305/ GB/T 12770-2002GB/T12771-2002

Length 200-1500m per coil, or As customer required

Stock size 6*1mm ,8*0.5mm ,8*0.6mm,8*0.8mm, 8*0.9mm,8*1mm, 9.5*1mm,10*1mm,ect..

Certificate ISO&BV

Packing way Woven bags,plastic bags etc.

Application range widely used in food industry, beverage equipment, beer machine, heat exchanger, milk/ water supply system, medical equipmentsolar energy, medical equipment, aviation, aerospace, communications, oil and other industries

Note OEM / ODM / Buyer Label accepted.

Size of Stainless steel Coil Tube

ITEM

Grade

Size

(MM)

Pressure

(Mpa)

Length

(M)

1

316L、304L、304 alloy 625 825 2205 2507

1/8″×0.025″

3200

500-35000

2

316L、304L、304 alloy 625 825 2205 2507

1/8″×0.035″

3200

500-35000

3

316L、304L、304 alloy 625 825 2205 2507

1/4″×0.035″

2000

500-35000

4

316L、304L、304 alloy 625 825 2205 2507

1/4″×0.049″

2000

500-35000

5

316L、304L、304 alloy 625 825 2205 2507

3/8″×0.035″

1500

500-35000

6

316L、304L、304 alloy 625 825 2205 2507

3/8″×0.049″

1500

500-35000

7

316L、304L、304 alloy 625 825 2205 2507

1/2″×0.049″

1000

500-35000

8

316L、304L、304 alloy 625 825 2205 2507

1/2″×0.065″

1000

500-35000

9

316L、304L、304 alloy 625 825 2205 2507

φ3mm×0.7mm

3200

500-35000

10

316L、304L、304 alloy 625 825 2205 2507

φ3mm×0.9mm

3200

500-35000

11

316L、304L、304 alloy 625 825 2205 2507

φ4mm×0.9mm

3000

500-35000

12

316L、304L、304 alloy 625 825 2205 2507

φ4mm×1.1mm

3000

500-35000

13

316L、304L、304 alloy 625 825 2205 2507

φ6mm×0.9mm

2000

500-35000

14

316L、304L、304 alloy 625 825 2205 2507

φ6mm×1.1mm

2000

500-35000

15

316L、304L、304 alloy 625 825 2205 2507

φ8mm×1mm

1800

500-35000

16

316L、304L、304 alloy 625 825 2205 2507

φ8mm×1.2mm

1800

500-35000

17

316L、304L、304 alloy 625 825 2205 2507

φ10mm×1mm

1500

500-35000

18

316L、304L、304 alloy 625 825 2205 2507

φ10mm×1.2mm

1500

500-35000

19

316L、304L、304 alloy 625 825 2205 2507

φ10mm×2mm

500

500-35000

20

316L、304L、304 alloy 625 825 2205 2507

φ12mm×1.5mm

500

500-35000

Pressure tables

Selection of the appropriate material for any given control or chemical injection line is subject to the prevailing operational and site conditions. In order to assist in the selection, the following tables provide internal pressure ratings and the adjustments factors for a range of common grades and sizes of seamless and laser welded stainless tubing.

Maximum pressure (P) for TP 316L at 100°F (38°C)1)

Please refer to grade and product form adjustment factors below.

Outside diameter, in. Wall thickness, in. Working pressure2) Burst pressure2) Collapse pressure4)

psi (MPa) psi (MPa) psi (MPa)

1/4 0.035 6,600 (46) 22,470 (155) 6,600 (46)

1/4 0.049 9,260 (64) 27,400 (189) 8,710 (60)

1/4 0.065 12,280 (85) 34,640 (239) 10,750 (74)

3/8 0.035 4,410 (30) 19,160 (132) 4,610 (32)

3/8 0.049 6,170 (43) 21,750 (150) 6,220 (43)

3/8 0.065 8,190 (56) 25,260 (174) 7,900 (54)

3/8 0.083 10,450 (72) 30,050 (207) 9,570 (66)

1/2 0.049 4,630 (32) 19,460 (134) 4,820 (33)

1/2 0.065 6,140 (42) 21,700 (150) 6,200 (43)

1/2 0.083 7,840 (54) 24,600 (170) 7,620 (53)

5/8 0.049 3,700 (26) 18,230 (126) 3,930 (27)

5/8 0.065 4,900 (34) 19,860 (137) 5,090 (35)

5/8 0.083 6,270 (43) 26,910 (151) 6,310 (44)

3/4 0.049 3,080 (21) 17,470 (120) 3,320 (23)

3/4 0.065 4,090 (28) 18,740 (129) 4,310 (30)

3/4 0.083 5,220 (36) 20,310 (140) 5,380 (37)

1) Estimates only. Actual pressures should be calculated considering all stress factors in the system.

2) Based on calculations from API 5C3, using a wall tolerance of +/-10%

3) Based on ultimate strength burst calculations from API 5C3

4) Based on yield strength collapse calculations from API 5C3

Adjustment factors for working pressure limits1)

Pw = reference working pressure rating for TP 316L at 100°F (38°C). To determine working pressure for grade/temperature combination, multiply Pw by adjustment factor.

Grade 100°F 200°F 300°F 400°F

(38°C) (93°C) (149°C) (204°C)

TP 316L, seamless 1 0.87 0.7 0.63

TP 316L, welded 0.85 0.74 0.6 0.54

Alloy 825, seamless 1.33 1.17 1.1 1.03

Alloy 825, welded 1.13 1.99 1.94 0.88

1) Adjustment factors based on allowable stress in ASME.

Adjustment factors for burst pressure limits1)

Pb = reference burst pressure for TP 316L at 100°F. To determine burst pressure for grade/temperature combination, multiply Pb by adjustment factor.

Grade 100°F 200°F 300°F 400°F

(38°C) (93°C) (149°C) (204°C)

TP 316L, seamless 1 0.93 0.87 0.8

TP 316L, welded 0.85 0.79 0.74 0.68

Alloy 825, seamless 1.13 1.07 1 0.87

Alloy 825, welded 0.96 0.91 0.85 0.74

1) Adjustment factors based on ultimate strength in ASME.

▼Stainless steel coiled tubing /coiled tubes material grade:

U.S.A.

GERMANY

GERMANY

FRANCE

JAPAN

ITALY

SWEDEN

U.K.

E.U.

SPAIN

RUSSIA

AISI

DIN 17006

W.N. 17007

AFNOR

JIS

UNI

SIS

BSI

EURONORM

201

SUS 201

301

X 12 CrNi 17 7

1.4310

Z 12 CN 17-07

SUS 301

X 12 CrNi 1707

23 31

301S21

X 12 CrNi 17 7

X 12 CrNi 17-07

302

X 5 CrNi 18 7

1.4319

Z 10 CN 18-09

SUS 302

X 10 CrNi 1809

23 31

302S25

X 10 CrNi 18 9

X 10 CrNi 18-09

12KH18N9

303

X 10 CrNiS 18 9

1.4305

Z 10 CNF 18-09

SUS 303

X 10 CrNiS 1809

23 46

303S21

X 10 CrNiS 18 9

X 10 CrNiS 18-09

303 Se

Z 10 CNF 18-09

SUS 303 Se

X 10 CrNiS 1809

303S41

X 10 CrNiS 18-09

12KH18N10E

304

X 5 CrNi 18 10

X 5 CrNi 18 12

1.4301

1.4303

Z 6 CN 18-09

SUS 304

X 5 CrNi 1810

23 32

304S15

304S16

X 6 CrNi 18 10

X 6 CrNi 19-10

08KH18N10

06KH18N11

304 N

SUS 304N1

X 5 CrNiN 1810

304 H

SUS F 304H

X 8 CrNi 1910

X 6 CrNi 19-10

304 L

X 2 CrNi 18 11

1.4306

Z 2 CN 18-10

SUS 304L

X 2 CrNi 1911

23 52

304S11

X 3 CrNi 18 10

X 2 CrNi 19-10

03KH18N11

X 2 CrNiN 18 10

1.4311

Z 2 CN 18-10-Az

SUS 304LN

X 2 CrNiN 1811

23 71

305

Z 8 CN 18-12

SUS 305

X 8 CrNi 1812

23 33

305S19

X 8 CrNi 18 12

X 8 CrNi 18-12

Z 6 CNU 18-10

SUS XM7

X 6 CrNiCu 18 10 4 Kd

309

X 15 CrNiS 20 12

1.4828

Z 15 CN 24-13

SUH 309

X 16 CrNi 2314

309S24

X 15 CrNi 23 13

309 S

SUS 309S

X 6 CrNi 2314

X 6 CrNi 22 13

310

X 12 CrNi 25 21

1.4845

SUH 310

X 22 CrNi 2520

310S24

20KH23N18

310 S

X 12 CrNi 25 20

1.4842

Z 12 CN 25-20

SUS 310S

X 5 CrNi 2520

23 61

X 6 CrNi 25 20

10KH23N18

314

X 15 CrNiSi 25 20

1.4841

Z 12 CNS 25-20

X 16 CrNiSi 2520

X 15 CrNiSi 25 20

20KH25N20S2

316

X 5 CrNiMo 17 12 2

1.4401

Z 6 CND 17-11

SUS 316

X 5 CrNiMo 1712

23 47

316S31

X 6 CrNiMo 17 12 2

X 6 CrNiMo 17-12-03

316

X 5 CrNiMo 17 13 3

1.4436

Z 6 CND 17-12

SUS 316

X 5 CrNiMo 1713

23 43

316S33

X 6 CrNiMo 17 13 3

X 6 CrNiMo 17-12-03

316 F

X 12 CrNiMoS 18 11

1.4427

316 N

SUS 316N

316 H

SUS F 316H

X 8 CrNiMo 1712

X 5 CrNiMo 17-12

316 H

X 8 CrNiMo 1713

X 6 CrNiMo 17-12-03

316 L

X 2 CrNiMo 17 13 2

1.4404

Z 2 CND 17-12

SUS 316L

X 2 CrNiMo 1712

23 48

316S11

X 3 CrNiMo 17 12 2

X 2 CrNiMo 17-12-03

03KH17N14M2

X 2 CrNiMoN 17 12 2

1.4406

Z 2 CND 17-12-Az

SUS 316LN

X 2 CrNiMoN 1712

316 L

X 2 CrNiMo 18 14 3

1.4435

Z 2 CND 17-13

X 2 CrNiMo 1713

23 53

316S13

X 3 CrNiMo 17 13 3

X 2 CrNiMo 17-12-03

03KH16N15M3

X 2 CrNiMoN 17 13 3

1.4429

Z 2 CND 17-13-Az

X 2 CrNiMoN 1713

23 75

X 6 CrNiMoTi 17 12 2

1.4571

Z6 CNDT 17-12

X 6 CrNiMoTi 1712

23 50

320S31

X 6 CrNiMoTi 17 12 2

X 6 CrNiMoTi 17-12-03

08KH17N13M2T

10KH17N13M2T

X 10 CrNiMoTi 18 12

1.4573

X 6 CrNiMoTi 1713

320S33

X 6 CrNiMoTI 17 13 3

X 6 CrNiMoTi 17-12-03

08KH17N13M2T

10KH17N13M2T

X 6 CrNiMoNb 17 12 2

1.4580

Z 6 CNDNb 17-12

X 6 CrNiMoNb 1712

X 6 CrNiMoNb 17 12 2

08KH16N13M2B

X 10 CrNiMoNb 18 12

1.4583

X 6 CrNiMoNb 1713

X 6 CrNiMoNb 17 13 3

09KH16N15M3B

317

SUS 317

X 5 CrNiMo 1815

23 66

317S16

317 L

X 2 CrNiMo 18 16 4

1.4438

Z 2 CND 19-15

SUS 317L

X 2 CrNiMo 1815

23 67

317S12

X 3 CrNiMo 18 16 4

317 L

X 2 CrNiMo 18 16 4

1.4438

Z 2 CND 19-15

SUS 317L

X 2 CrNiMo 1816

23 67

317S12

X 3 CrNiMo 18 16 4

330

X 12 NiCrSi 36 16

1.4864

Z 12NCS 35-16

SUH 330

321

X 6 CrNiTi 18 10

X 12 CrNiTi 18 9

1.4541

1.4878

Z 6 CNT 18-10

SUS 321

X 6 CrNiTi 1811

23 37

321S31

X 6 CrNiTi 18 10

X 6 CrNiTi 18-11

08KH18N10T

321 H

SUS 321H

X 8 CrNiTi 1811

321S20

X 7 CrNiTi 18-11

12KH18N10T

329

X 8 CrNiMo 27 5

1.4460

SUS 329J1

23 24

347

X 6 CrNiNb 18 10

1.4550

Z 6 CNNb 18-10

SUS 347

X 6 CrNiNb 1811

23 38

347S31

X 6 CrNiNb 18 10

X 6 CrNiNb 18-11

08KH18N12B

347 H

SUS F 347H

X 8 CrNiNb 1811

X 7 CrNiNb 18-11

904L

1.4939

Z 12 CNDV 12-02

X 20 CrNiSi 25 4

1.4821

UNS31803

X 2 CrNiMoN 22 5

1.4462

UNS32760

X 3 CrNiMoN 25 7

1.4501

Z 3 CND 25-06Az

403

X 6 Cr 13

X 10 Cr 13

X 15 Cr 13

1.4000

1.4006

1.4024

Z 12 C 13

SUS 403

X 12 Cr 13

23 02

403S17

X 10 Cr 13

X 12 Cr 13

X 6 Cr 13

12Kh13

405

X 6 CrAl 13

1.4002

Z 6 CA 13

SUS 405

X 6 CrAl 13

405S17

X 6 CrAl 13

X 6 CrAl 13

X 10 CrAl 7

1.4713

Z 8 CA 7

X 10 CrAl 7

X 10 CrAl 13

1.4724

X 10 CrAl 12

10Kh13SYu

X 10 CrAl 18

1.4742

X 10 CrSiAl 18

15Kh18SYu

409

X 6 CrTi 12

1.4512

Z 6 CT 12

SUH 409

X 6 CrTi 12

409S19

X 5 CrTi 12

X 2 CrTi 12

410

X 6 Cr 13

X 10 Cr 13

X 15 Cr 13

1.4000

1.4006

1.4024

Z 10 C 13

Z 12 C 13

SUS 410

X 12 Cr 13

23 02

410S21

X 12 Cr 13

X 12 Cr 13

12Kh13

410 S

X 6 Cr 13

1.4000

Z 6 C 13

SUS 410S

X 6 Cr 13

23 01

403S17

X 6 Cr 13

08Kh13

414

Factory

pipe factory_副本

Quality advantage:

The quality of our products for the control line in oil and gas sector is assured not just during the controlled manufacturing process but also by way of finished product testing. Typical tests include:

1.Non-destructive tests

2. Hydrostatic tests

3.Surface finish controls

4. Dimensional accuracy measurements

5.Flare and coning tests

6. Mechanical and chemical property testing

Application caillary tube

1) Medical device industry

2) temperature-guided industrial temperature control, sensors used pipe, tube thermometer

3) Pens care industry core tube

4) micro-tube antenna, various types of small precision stainless steel antenna

5) With a variety of electronic small-diameter Stainless steel capillary

6) Jewelry needle punch

7) Watches, picture

8) Car antenna tube, bar antennas using tubes, antenna tube

9) Laser engraving equipment to use stainless steel tube

10) Fishing gear, accessories, Yugan out with possession of

11) Diet with stainless steel capillary

12) all types of mobile phone stylus a computer stylus

13) Heating pipe industry, oil industry

14) Printers, silent box needle

15) Pull a double-melt stainless steel tube used in window-coupled

16) A variety of industrial small diameter Precision stainless steel tubes

17) Precision dispensing with stainless steel needles

18) Microphone, headphones and microphone to use stainless steel tube, and so on

pipe packging

222