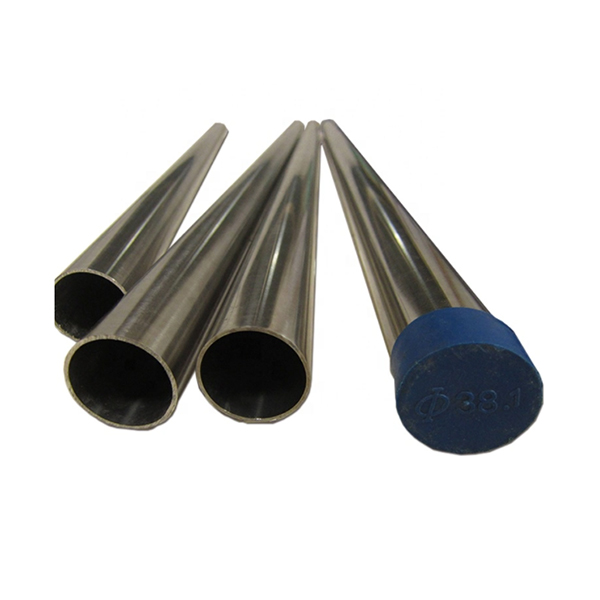

2022 Latest Design Hot Rolled Seamless Steel Tube - Precision steel seamless hydraulic pipe for automobile pipeline – Zheyi

2022 Latest Design Hot Rolled Seamless Steel Tube - Precision steel seamless hydraulic pipe for automobile pipeline – Zheyi Detail:

Precision steel pipe, It is a high precision steel tube material. The main categories are: precision seamless steel pipe, precision hydraulic seamless steel pipe, cold drawn precision seamless steel pipe, cold rolled precision seamless steel pipe, high precision seamless steel pipe, precision bright seamless steel pipe.

Precision steel pipe, Precision hydraulic seamless steel pipe, cold drawn precision seamless steel pipe, cold rolled precision seamless steel pipe, high precision seamless steel pipe, precision bright seamless steel pipe.

(1) Main varieties of steel pipe: DIN series high precision and bright seamless steel pipe, special steel pipe for hydraulic system, special steel pipe for automobile manufacturing

(2) Main standards: DIN2391, DIN2445, EN10305, DIN1629, DIN1630, ASTM A179

(3) Main material: ST35 (E235) ST37.4 ST45 (E255) ST52 (E355)

(4) Main delivery status: NBK (+N) GBK (+A) BK (+C) BKW (+LC) BKS (+SR)

(5) Main features: No oxide layer on the inner and outer walls of the steel pipe, no leakage under high pressure, high precision, high finish, no deformation in cold bending, no cracks in flaring and flattening.

Precision steel pipe, Chemical composition of carbon C, Silicon Si, Manganese Mn, sulfur S, phosphorus P, Cr.

Precision Steel Pipe, Product Features

1. Smaller outside diameter.

2. High precision can do small batch production

3. Cold-drawn products have high precision and good surface quality.

4. The cross area of steel pipe is more complex.

5. The performance of steel pipe is superior, and the metal is dense.

Production And Manufacturing Methods

According to different production methods, it can be divided into hot rolled tube, cold rolled tube, cold drawn tube, extrusion tube and so on.

1.1 Hot rolled seamless pipes are generally produced on automatic pipe rolling sets. The solid tube blank is checked and cleared of surface defects, cut into the required length, centering on the perforated end face of the tube blank, and then sent to the heating furnace for heating, and perforated on the punch machine. In the perforation at the same time continuous rotation and forward, under the action of the roll and the top, the tube blank gradually formed a cavity, called the wool tube. Then it is sent to the automatic pipe mill to continue rolling. Finally, the wall thickness of the whole machine is adjusted, and the sizing machine is adjusted to meet the specification requirements. It is an advanced method to produce hot rolled seamless steel tube with continuous rolling tube set.

1.2 If you want to obtain seamless tubes with smaller size and better quality, you must use cold rolling, cold drawing or a combination of both methods. Cold rolling is usually carried out on a two-high mill. The steel pipe is rolled in an annular pass consisting of a circular groove with a variable section and a stationary conical top. Cold drawing is usually carried out in 0.5 ~ 100T single chain or double chain cold drawing machine.

1.3. Extrusion method: The heated tube blank is placed in a closed extrusion cylinder, and the perforated rod moves together with the extrusion rod to extrude the extruded parts from the smaller die hole. This method can produce smaller diameter steel pipe.

Precision Steel Pipe, Use

2.1, seamless pipe is widely used. General purpose seamless pipe by ordinary carbon structural steel, low alloy structural steel or alloy structural steel rolling, production is the most, mainly used for conveying fluid pipes or structural parts.

2.2. Supply in three categories according to different uses: a. Supply in accordance with chemical composition and mechanical properties; B. Supply according to mechanical properties; C. Supply according to water pressure test. Steel tubes supplied under class A and CLASS B, if used to withstand liquid pressure, are also subjected to hydrostatic test.

2.3, special use of seamless tube boiler seamless tube, geological seamless tube and oil seamless tube, etc.

Precision Steel Pipe, Type

3.1 Seamless steel tube can be divided into hot rolled tube, cold rolled tube, cold drawn tube and extruded tube according to different production methods.

3.2 according to the shape classification, there are circular pipes and special-shaped pipes. Special-shaped tube except square tube and rectangular tube, there are elliptical tube, semicircle tube, triangle tube, hexagonal tube, convex tube, plum tube and so on.

3.3, according to the different materials, it is divided into ordinary carbon structure tube, low alloy structure tube, high quality carbon structure tube, alloy structure tube, stainless tube and so on.

3.4. According to special purposes, there are boiler pipes, geological pipes, oil pipes, etc.

Specifications And Appearance Quality

Seamless pipe according to GB/T8162-87

4.1 Specification: Hot-rolled pipe diameter 32 ~ 630mm. The wall thickness is 2.5 ~ 75mm. Cold rolled (cold drawn) tube diameter 5 ~ 200mm. The wall thickness is 2.5 ~ 12mm.

4.2 Appearance quality: The internal and external surface of the steel pipe shall not have cracks, folding, rolling, lamination, hair lines and scar defects. These defects shall be completely removed without allowing wall thickness and od to exceed negative deviations.

4.3 Both ends of the steel pipe should be cut at right angles and burrs removed. Steel pipes with wall thickness greater than 20mm allow gas cutting and hot saw cutting. By the agreement of both sides of supply and demand also can not cut the head.

4.4 “Surface Quality” of cold-drawn or cold-rolled precision seamless steel pipe refer to GB3639-83.

Chemical Composition Test

5.1 The chemical composition of domestic seamless tubes supplied according to chemical composition and mechanical properties, such as Steel No. 10, 15, 20, 25, 30, 35, 40, 45 and 50, shall conform to the requirements of GB/T699-88. Imported seamless pipes shall be inspected according to relevant standards stipulated in the contract. The chemical composition of 09MnV, 16Mn, 15MnV steel should comply with the provisions of GB1591-79.

5.2 Refer to gb223-84 “Methods for Chemical Analysis of Steel and Alloy” for specific analysis methods.

5.3. Refer to GB222-84 “Allowable Deviation of chemical Composition of steel samples and Finished products for chemical Analysis”.

Physical Performance Test

6.1 For domestic seamless pipes supplied according to the mechanism performance, ordinary carbon steel shall be made according to GB/T700-88 Class A steel (but the sulfur content shall not exceed 0.050% and phosphorus content shall not exceed 0.045%), and its mechanical properties shall conform to the values specified in table GB8162-87.

6.2 The domestic seamless pipes supplied according to the hydrostatic test must meet the hydrostatic test stipulated in the standard.

6.3 Physical performance inspection of imported seamless tubes shall be carried out according to relevant standards stipulated in the contract.

Specification

ASTM A106/ASME SA106 is the standard specification for seamless carbon steel pipe applied for high temperature services. It includes three grades A, B and C, and common use grade is A106 Grade B. It used in different industries not only for pipeline systems like oil and gas, water, mineral slurry transmission, but also for boiler, construction, structural purposes.

ASTM A106 Grade B pipe is equivalent to ASTM A53 Grade B and API 5L B on chemical position and mechanical properties, in general use carbon steel and yiled strength minimum 240 MPa, tensile strength 415 Mpa.

Below will explain ASTM A106 Grade B pipe from different aspects.

| ASTM A106 grade b Chemical Composition | |||

|

Grade A |

Grade B |

Grade C |

|

|

Carbon max. % |

0.25 |

0.3 |

0.35 |

|

Manganese % |

0.27 to 0.93 |

0.29 to 1.06 |

0.29 to 1.06 |

|

Phosporous, max. % |

0.025 |

0.025 |

0.025 |

|

Sulfur, max. % |

0.025 |

0.025 |

0.025 |

|

Silicon, min. % |

0.1 |

0.1 |

0.1 |

| ASTM A106 Grade B Pipe Yield and Tensile Strength | |||

|

Seamless |

Grade A |

Grade B |

Grade C |

|

Tensile Strength, min., psi |

48,000 |

60,000 |

70,000 |

|

Yield Strength, min., psi |

30,000 |

35,000 |

40,000 |

| ASTM A106 Gr B Equivalent | ||||

| Former | New | |||

| Execution | Standard | Material | European Standard | Material |

| Seamless | API 5L | Grade X52 | EN 10208-2 | L360NB |

| Seamless | ASTM A333 | GRADE 6 | EN 10216-4 | P265NL |

| Welded | API 5L | Grade B | EN 10208-2 | L245NB |

| Seamless | ASTM A106 | GRADE B | EN 10216-2 | P265GH |

| Seamless | API 5L | Grade B | EN 10208-2 | L245NB |

| Welded | API 5L | Grade X52 | EN 10208-2 | L360NB |

| ASTM A106 Grade B Pipe Types | Out diameter | Wall thickness | Length |

| ASTM A106 Grade B SAW Pipe | 16″ NB – 100″ NB | As per requirement | Custom |

| ASTM A106 Grade B ERW Pipe (Custom Sizes) | 1/2″ NB – 24″ NB | As per requirement | Custom |

| ASTM A106 Grade B Welded Pipe (in Stock + Custom Sizes) | 1/2″ NB – 24″ NB | As per requirement | Custom |

| ASTM A106 Grade B Seamless Pipe (Custom Sizes) | 1/2″ NB – 60″ NB | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Custom |

| ASTM Standard for seamless steel pipe | ||

| Executive Standard | Grade / Material | Product Name |

| ASTM A53 | A, B | Black and Hot-Dipped Zinc-Coated Steel Pipes Welded and Seamless |

| ASTM A106 | A, B | Seamless Carbon Steel for High Temperature Service |

| ASTM A179 | Low Carbon Steel | Seamless Cold-Drawn Low-Carbon Steel Heat Exchanger and Condenser Tubes |

| ASTM A192 | Low Carbon Steel | Seamless Carbon Steel Boiler Tubes for High Pressure |

| ASTM A210 | A1, C | Seamless Medium-Carbon and Alloy Steel Boiler and Superheater Tubes |

| ASTM A213 | T5, T11, T12, T22 | Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

| TP 347H | ||

| ASTM A312 | TP304/304L, TP316/316L | Seamless Steel Pipe for Stainless Materials |

| ASTM A333 | Gr.6 | Seamless and Welded Steel Pipe for Low-Temperature Service |

| ASTM A335 | P9, P11, P22 | Seamless Ferritic Alloy Steel Pipe for High-Temperature Service |

| ASTM A519 | 41,304,140 | Seamless Carbon and Alloy Steel for Mechanical Tubing |

| ASTM A789 | Seamless Ferritic/Austenitic Stainless Steel Tubing for General Service | |

| API Standard for seamless steel pipe | ||

| Executive Standard | Grade / Material | Product Name |

| API Spec 5CT | J55, K55, N80, L80,C90, C95, T95, P110, M65 | Spectification for Casing and Tubing |

| API Spec 5L PSL1 / PSL2 | A,B X42, X46, X52, X56, X60, X65,. X70 | Specification for Line Pipe |

| DIN / EN Standard for seamless steel pipe | ||

| Executive Standard | Grade / Material | Product Name |

| DN 17175/EN10216-2 | ST35, ST45, ST52, 13CrMo44 | Seamless Steel Tube for Elevated Temperature |

| DIN 2391/EN10305-1 | St35, St45, St52 | Cold Drawn Seamless Precision Pipe |

| DIN 1629/EN10216-1 | St37, St45, St52 | Seamless Circular unalloyed Steel Tubes Subject to Special Requirments |

Product Display

Product detail pictures:

Related Product Guide:

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of 2022 Latest Design Hot Rolled Seamless Steel Tube - Precision steel seamless hydraulic pipe for automobile pipeline – Zheyi , The product will supply to all over the world, such as: Ethiopia, Mongolia, Bhutan, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.