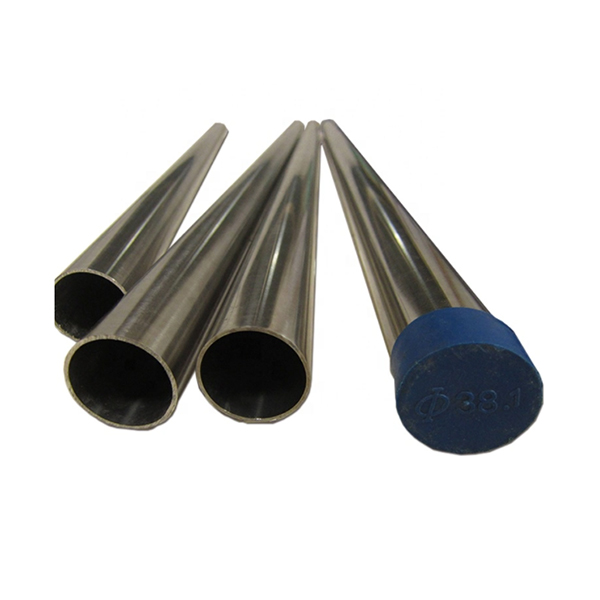

201 Cold Rolled Stainless Steel Pipes

As an important part of steel products, steel pipes are divided into two categories: seamless steel pipes (round billets) and welded steel pipes (slabs) due to their different manufacturing processes and the shape of the pipe blanks used. Generally, seamless steel pipes are made of 10, 20, 30, 35, and 45 high-quality carbon steel and 16Mn, 5MnV low-alloy structural steel or 30CrMnSi, 40Cr, 45Mn2, 40MnB alloy steel through hot rolling or cold rolling.

Hot rolled (extruded) seamless steel pipes:

Hot rolling is relative to cold rolling. Cold rolling is performed below the recrystallization temperature, and hot rolling is performed above the recrystallization temperature. Hot-rolled seamless steel pipes are generally divided into low, medium, and high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes, and other steel pipes. The outer diameter of the hot-rolled seamless pipe is generally greater than 32mm, and the wall thickness is 2.5-75mm.

Advantages of hot rolled seamless steel pipe:

Hot-rolled seamless steel pipe can destroy the casting structure of the steel ingot, refine the grain of the steel, eliminate the defects in the structure, make the structure of the steel dense, and improve the mechanical properties. This improvement is reflected in the rolling direction so that the steel is no longer isotropic to a certain extent; the bubbles, cracks, and osteoporosis formed during pouring can also be welded together under high temperature and high pressure.

There are two main types of stainless steel seamless steel pipes: cold-rolled seamless steel pipes and hot-rolled seamless steel pipes. The differences between them are clear and each has advantages and disadvantages.

The difference

First, local buckling of the material. The section of the cold-rolled stainless steel pipe can have local buckling to better utilize the bearing capacity of the pipe after buckling, while the section of the hot-rolled stainless steel pipe cannot have local buckling.

Secondly, the distribution of the cross-section is also very different due to the difference in the residual stress. Effect of cross-sectional stress distribution of residual cold-formed stainless steel on bent profiles, and effect of residual hot-rolled steel cross-sectional stress distribution on film properties.

In addition, the free torsional stiffness of the hot-rolled stainless steel pipe is higher than that of the cold-rolled steel pipe, so the torsional performance of the hot-rolled stainless steel pipe is better than that of the cold-rolled stainless steel pipe.

Seamless steel pipe series products are widely used in petrochemical, marine engineering, aerospace, and other fields due to their advantages of corrosion resistance, high-temperature resistance, and high-pressure resistance. According to statistics, there are more than 6,000 cold-rolled pipe mills in the market, but they are basically in the status quo of low production efficiency, slow rolling speed, and low product precision. As market positioning and application scenarios place higher requirements on product specifications (increased diameter-to-wall ratio), product accuracy (roundness, straightness, and surface finish) and product performance (nickel-based alloys, duplex stainless steel, etc.), traditional capabilities The requirements for equipment and functions are getting higher and higher, and they are developing towards extreme, high-speed, intelligent, high-precision, and more functions, thus promoting the rapid development of equipment and putting forward higher requirements for structural design, equipment level and performance. Manufacturing precision of circulating cold rolling mills. The cold rolling mill will develop in the direction of extreme, high speed, intelligence, high precision, and multi-function.

Specifications

| Product Name | Stainless Steel Seamless Pipe | |

| Steel grade | 300 series | |

| Standard | ASTM A213, A312, ASTM A269, ASTM A778, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 | |

| Material | 304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 304N, 3 16L, 316N, 201, 202 | |

| Surface | Polishing, annealing, pickling, bright | |

| Type | hot rolled and cold rolled | |

| stainless steel round pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8"-100") | |

| stainless steel square pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 4mm*4mm-800mm*800mm | |

| stainless steel rectangular pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8"-100") | |

| Length | 4000mm, 5800mm, 6000mm, 12000mm, or as required. | |

| Trade terms | Price terms | FOB, CIF, CFR, CNF, Ex-work |

| Payment terms | T/T, L/C, westen union | |

| Delivery time | Prompt delivery or as the order quantity. | |

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Italy, India, Egypt, Oman, Malaysia, Kuwait, Canada, Viet Nam, Peru, Mexico, Dubai, Russia, etc | |

| Package | Standard export seaworthy package, or as required. | |

| Application | Widely used in petroleum, foodstuff, chemical industry, construction, electric power, nuclear, energy, machinery, biotechnology, paper making, shipbuilding, boiler fields. Pipes also can be made according to the customer's required. |

|

| Contact | If you have any questions, please feel free to contact me. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

Chemical Composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Product Display