100% Original China Cold Drawn Carbon Seamless Steel Pipe for Mechanical Processing API5l Line Pipe ERW Pipe

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for 100% Original China Cold Drawn Carbon Seamless Steel Pipe for Mechanical Processing API5l Line Pipe ERW Pipe, We often keep on with the principle of “Integrity, Efficiency, Innovation and Win-Win business”. Welcome to go to our website and never hesitate to communicate with us. Are you all set? ? ? Let us go!!!

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for China Welded Steel Pipes and Carbon Steel Pipe, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Cold Drawn Seamless Mechanical Tube, It is used for precision cold-drawn seamless pipe with high dimensional accuracy and good surface finish for mechanical structure and hydraulic equipment. The choice of precision seamless tube manufacturing machinery structure or hydraulic equipment, can greatly save the machining hours, improve the utilization rate of materials, and help to improve product quality.

Cold Drawn Seamless Mechanical Tube, If you want to obtain smaller size and better quality of small caliber seamless steel pipe, must use cold rolling, cold drawing or both combined methods. Cold rolling is usually carried out on a two-high mill. The steel pipe is rolled in an annular pass consisting of a circular groove with a variable section and a stationary conical top. Cold drawing is usually carried out in 0.5 ~ 100T single chain or double chain cold drawing machine.

High quality carbon structural steel cold dip seamless pipe, mainly made of no. 10, 20, 35, 45 steel, in addition to ensure chemical composition and mechanical properties to do water pressure test, crimping, flaring, flattening test.

Weight calculation formula of cold-drawn seamless steel tube: (outer diameter – wall thickness)* wall thickness *0.02466=kg/ m (weight per meter)

Cold Drawn Seamless Mechanical Tube, A Formula To Calculate

[(outer diameter - wall thickness)* wall thickness]*0.02466=kg/ m (weight per meter)

Cold Drawn Seamless Mechanical Tube, Manufacturing Method

According to different production methods, it can be divided into hot rolled tube, cold rolled tube, cold drawn tube, extrusion tube and so on. Cold drawn seamless steel tube with hot rolled seamless steel tube is the biggest difference between cold drawn seamless steel tube precision is better than hot rolled seamless steel tube, cold drawn seamless steel tube of the general accuracy about 20 silk, and the precision of the hot-rolled seamless pipe in about 100 silk, so cold drawn seamless steel tube is a mechanical processing manufacturing industry, the first selection of parts and components manufacturing.

1.1. Cold Drawn Seamless Mechanical Tube, Generally, it is produced on automatic pipe rolling set. The solid tube blank is checked and cleared of surface defects, cut into the required length, centering on the perforated end face of the tube blank, and then sent to the heating furnace for heating, and perforated on the punch machine. In the perforation at the same time continuous rotation and forward, under the action of the roll and the top, the tube blank gradually formed a cavity, called the wool tube. Then it is sent to the automatic pipe mill to continue rolling. Finally, the wall thickness of the whole machine is even, and the sizing (reducing) machine is sizing (reducing) to meet the specification requirements. It is an advanced method to produce hot rolled seamless steel tube with continuous rolling tube set.

1.2. Extrusion method: The heated tube blank is placed in a closed extrusion cylinder, and the perforated rod moves together with the extrusion rod to extrude the extruded parts from the smaller die hole. This method can produce smaller diameter steel pipe.

Use

2.1, seamless pipe is widely used. General purpose seamless pipe by ordinary carbon structural steel, low alloy structural steel or alloy structural steel rolling, production is the most, mainly used for conveying fluid pipes or structural parts.

2.2. Supply in three categories according to different uses: a. Supply in accordance with chemical composition and mechanical properties; B. Supply according to mechanical properties; C. Supply according to water pressure test. Steel tubes supplied under class A and CLASS B, if used to withstand liquid pressure, are also subjected to hydrostatic test.

2.3, special use of seamless tube boiler seamless tube, geological seamless tube and oil seamless tube, etc.

Cold Drawn Seamless Mechanical Tube, species

3.1 Seamless steel tube can be divided into hot rolled tube, cold rolled tube, cold drawn tube and extruded tube according to different production methods.

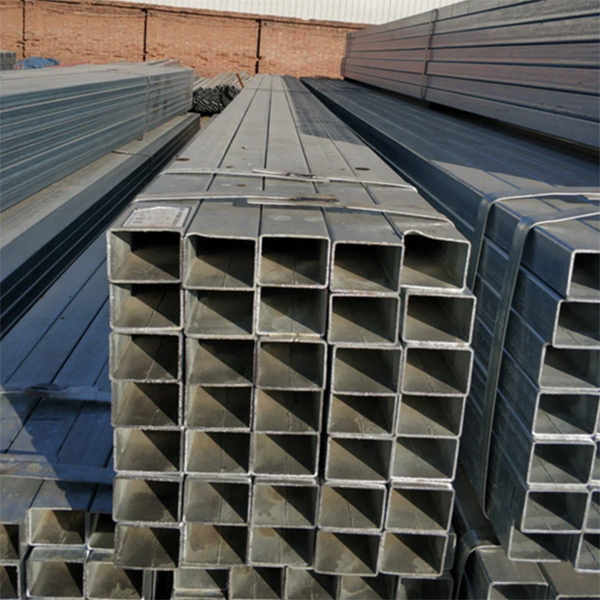

3.2 according to the shape classification, there are circular pipes and special-shaped pipes. Special-shaped tube except square tube and rectangular tube, there are elliptical tube, semicircle tube, triangle tube, hexagonal tube, convex tube, plum tube and so on.

3.3, according to the different materials, it is divided into ordinary carbon structure tube, low alloy structure tube, high quality carbon structure tube, alloy structure tube, stainless tube and so on.

3.4. According to special purposes, there are boiler pipes, geological pipes, oil pipes, etc.

Specifications and appearance quality

Seamless pipe according to GB/T8162-2018 regulations

4.1 Specification: Hot-rolled pipe diameter 32 ~ 630mm. The wall thickness is 2.5 ~ 75mm. Cold rolled (cold drawn) tube diameter 5 ~ 200mm. The wall thickness is 2.5 ~ 12mm.

4.2 Appearance quality: The internal and external surface of the steel pipe shall not have cracks, folding, rolling, lamination, hair lines and scar defects. These defects shall be completely removed without allowing wall thickness and od to exceed negative deviations.

4.3 Both ends of the steel pipe should be cut at right angles and burrs removed. Steel pipes with wall thickness greater than 20mm allow gas cutting and hot saw cutting. By the agreement of both sides of supply and demand also can not cut the head.

4.4 Cold-drawn or cold-rolled precision seamless steel pipe Surface Quality refer to GB3639-2018.

Component test

5. Chemical composition test

5.1 The chemical composition of domestic seamless tubes supplied according to chemical composition and mechanical properties, such as Steel No. 10, 15, 20, 25, 30, 35, 40, 45 and 50, shall conform to the requirements of GB/T699-88. Imported seamless pipes shall be inspected according to relevant standards stipulated in the contract. The chemical composition of 09MnV, 16Mn, 15MnV steel should comply with the provisions of GB1591-79.

5.2 Refer to gb223-84 “Methods for Chemical Analysis of Steel and Alloy” for specific analysis methods.

5.3. Refer to GB222-84 “Allowable Deviation of chemical Composition of steel samples and Finished products for chemical Analysis”.

Physical properties of

6.1 For domestic seamless pipes supplied according to mechanism performance, ordinary carbon steel shall be made according to GB/T700-88 Class A steel (but the sulfur content shall not exceed 0.050% and phosphorus content shall not exceed 0.045%), and its mechanical properties shall conform to the values specified in the TABLE GB8162-2008.

6.2 The domestic seamless pipes supplied according to the hydrostatic test must meet the hydrostatic test stipulated in the standard.

6.3 Physical performance inspection of imported seamless tubes shall be carried out according to relevant standards stipulated in the contract.

Packing Standard

According to gb2102-88. There are three kinds of steel tube packing: strapping, packing, oil strapping or oil packing.

Differences and Characteristics

The difference between cold-drawn precision steel pipe and ordinary seamless steel pipe:

1. General seamless steel pipe is mainly characterized by no welding joints and can bear large pressure. The product may be very rough cast or cold – drawn.

2. Cold-drawn precision steel pipe is a product emerging in recent years, mainly with strict tolerance and roughness of inner hole and outer wall size.

Features Of Cold Drawn (Rolled) Precision Steel Tube

1. Smaller outside diameter.

2. High precision can do small batch production

3. Cold drawing (rolling) finished products with high precision and good surface quality.

4. The cross area of steel pipe is more complex.

5. The performance of steel pipe is superior, and the metal is relatively dense.

Commonly Used Specifications

According to GB/T3639-2018 (cold drawn or cold rolled precision seamless steel pipe)

Specification sheet of cold-drawn seamless steel tube

| Φ4×0.5 | Φ16×0.5 | Φ26×1.8 | Φ35×9.0 | Φ48×5.0 | Φ70×2.8 | Φ90×10 | Φ130×14 | Φ190×14 |

| Φ4×0.8 | Φ16×0.8 | Φ26×2.0 | Φ35×10 | Φ48×5.5 | Φ70×3.0 | Φ90×12 | Φ130×16 | Φ190×16 |

| Φ4×1.0 | Φ16×1.0 | Φ26×2.2 | Φ38×0.5 | Φ48×6.0 | Φ70×3.5 | Φ90×14 | Φ130×18 | Φ190×18 |

| Φ4×1.2 | Φ16×1.2 | Φ26×2.5 | Φ38×0.8 | Φ48×7.0 | Φ70×4.0 | Φ90×16 | Φ140×2.5 | Φ190×20 |

| Φ5×0.5 | Φ16×1.5 | Φ26×2.8 | Φ38×1.0 | Φ48×8.0 | Φ70×4.5 | Φ95×2.0 | Φ140×2.8 | Φ190×22 |

| Φ5×0.8 | Φ16×1.8 | Φ26×3.0 | Φ38×1.2 | Φ48×9.0 | Φ70×5.0 | Φ95×2.2 | Φ140×3.0 | Φ200×3.5 |

| Φ5×1.0 | Φ16×2.0 | Φ26×3.5 | Φ38×1.5 | Φ48×10 | Φ70×5.5 | Φ95×2.5 | Φ140×3.5 | Φ200×4.0 |

| Φ5×1.2 | Φ16×2.2 | Φ26×4.0 | Φ38×1.8 | Φ50×1.0 | Φ70×6.0 | Φ95×2.8 | Φ140×4.0 | Φ200×4.5 |

| Φ6×0.5 | Φ16×2.5 | Φ26×4.5 | Φ38×2.0 | Φ50×1.2 | Φ70×7.0 | Φ95×3.0 | Φ140×4.5 | Φ200×5.0 |

| Φ6×0.8 | Φ16×2.8 | Φ26×5.0 | Φ38×2.2 | Φ50×1.5 | Φ70×8.0 | Φ95×3.5 | Φ140×5.0 | Φ200×5.5 |

| Φ6×1.0 | Φ16×3.0 | Φ26×5.5 | Φ38×2.5 | Φ50×1.8 | Φ70×9.0 | Φ95×4.0 | Φ140×5.5 | Φ200×6.0 |

| Φ6×1.2 | Φ16×3.5 | Φ26×6.0 | Φ38×2.8 | Φ50×2.0 | Φ70×10 | Φ95×4.5 | Φ140×6.0 | Φ200×7.0 |

| Φ6×1.5 | Φ16×4.0 | Φ26×7.0 | Φ38×3.0 | Φ50×2.2 | Φ70×12 | Φ95×5.0 | Φ140×7.0 | Φ200×8.0 |

| Φ6×1.8 | Φ16×4.5 | Φ26×8.0 | Φ38×3.5 | Φ50×2.5 | Φ70×14 | Φ95×5.5 | Φ140×8.0 | Φ200×9.0 |

| Φ6×2.0 | Φ16×5.0 | Φ28×0.5 | Φ38×4.0 | Φ50×2.8 | Φ75×1.0 | Φ95×6.0 | Φ140×9.0 | Φ200×10 |

| Φ7×0.5 | Φ16×5.5 | Φ28×0.8 | Φ38×4.5 | Φ50×3.0 | Φ75×1.2 | Φ95×7.0 | Φ140×10 | Φ200×12 |

| Φ7×0.8 | Φ16×6.0 | Φ28×1.0 | Φ38×5.0 | Φ50×3.5 | Φ75×1.5 | Φ95×8.0 | Φ140×12 | Φ200×14 |

| Φ7×1.0 | Φ18×0.5 | Φ28×1.2 | Φ38×5.5 | Φ50×4.0 | Φ75×1.8 | Φ95×9.0 | Φ140×14 | Φ200×16 |

| Φ7×1.2 | Φ18×0.8 | Φ28×1.5 | Φ38×6.0 | Φ50×4.5 | Φ75×2.0 | Φ95×10 | Φ140×16 | Φ200×18 |

| Φ7×1.5 | Φ18×1.0 | Φ28×1.8 | Φ38×7.0 | Φ50×5.0 | Φ75×2.2 | Φ95×12 | Φ140×18 | Φ200×20 |

| Φ7×1.8 | Φ18×1.2 | Φ28×2.0 | Φ38×8.0 | Φ50×5.5 | Φ75×2.5 | Φ95×14 | Φ150×3.0 | Φ200×22 |

| Φ7×2.0 | Φ18×1.5 | Φ28×2.2 | Φ38×9.0 | Φ50×6.0 | Φ75×2.8 | Φ95×16 | Φ150×3.5 | |

| Φ8×0.5 | Φ18×1.8 | Φ28×2.5 | Φ38×10 | Φ50×7.0 | Φ75×3.0 | Φ95×18 | Φ150×4.0 | |

| Φ8×0.8 | Φ18×2.0 | Φ28×2.8 | Φ40×0.5 | Φ50×8.0 | Φ75×3.5 | Φ100×2.0 | Φ150×4.5 | |

| Φ8×1.0 | Φ18×2.2 | Φ28×3.0 | Φ40×0.8 | Φ50×9.0 | Φ75×4.0 | Φ100×2.2 | Φ150×5.0 | |

| Φ8×1.2 | Φ18×2.5 | Φ28×3.5 | Φ40×1.0 | Φ50×10 | Φ75×4.5 | Φ100×2.5 | Φ150×5.5 | |

| Φ8×1.5 | Φ18×2.8 | Φ28×4.0 | Φ40×1.2 | Φ55×1.0 | Φ75×5.0 | Φ100×2.8 | Φ150×6.0 | |

| Φ8×1.8 | Φ18×3.0 | Φ28×4.5 | Φ40×1.5 | Φ55×1.2 | Φ75×5.5 | Φ100×3.0 | Φ150×7.0 | |

| Φ8×2.0 | Φ18×3.5 | Φ28×5.0 | Φ40×1.8 | Φ55×1.5 | Φ75×6.0 | Φ100×3.5 | Φ150×8.0 | |

| Φ8×2.2 | Φ18×4.0 | Φ28×5.5 | Φ40×2.0 | Φ55×1.8 | Φ75×7.0 | Φ100×4.0 | Φ150×9.0 | |

| Φ8×2.5 | Φ18×4.5 | Φ28×6.0 | Φ40×2.2 | Φ55×2.0 | Φ75×8.0 | Φ100×4.5 | Φ150×10 | |

| Φ9×0.5 | Φ18×5.0 | Φ28×7.0 | Φ40×2.5 | Φ55×2.2 | Φ75×9.0 | Φ100×5.0 | Φ150×12 | |

| Φ9×0.8 | Φ18×5.5 | Φ28×8.0 | Φ40×2.8 | Φ55×2.5 | Φ75×10 | Φ100×5.5 | Φ150×14 | |

| Φ9×1.0 | Φ18×6.0 | Φ30×0.5 | Φ40×3.0 | Φ55×2.8 | Φ75×12 | Φ100×6.0 | Φ150×16 | |

| Φ9×1.2 | Φ20×0.5 | Φ30×0.8 | Φ40×3.5 | Φ55×3.0 | Φ75×14 | Φ100×7.0 | Φ150×18 | |

| Φ9×1.5 | Φ20×0.8 | Φ30×1.0 | Φ40×4.0 | Φ55×3.5 | Φ75×16 | Φ100×8.0 | Φ150×20 | |

| Φ9×1.8 | Φ20×1.0 | Φ30×1.2 | Φ40×4.5 | Φ55×4.0 | Φ80×1.0 | Φ100×9.0 | Φ160×3.0 | |

| Φ9×2.0 | Φ20×1.2 | Φ30×1.5 | Φ40×5.0 | Φ55×4.5 | Φ80×1.2 | Φ100×10 | Φ160×3.5 | |

| Φ9×2.2 | Φ20×1.5 | Φ30×1.8 | Φ40×5.5 | Φ55×5.0 | Φ80×1.5 | Φ100×12 | Φ160×4.0 | |

| Φ9×2.5 | Φ20×1.8 | Φ30×2.0 | Φ40×6.0 | Φ55×5.5 | Φ80×1.8 | Φ100×14 | Φ160×4.5 | |

| Φ9×2.8 | Φ20×2.0 | Φ30×2.2 | Φ40×7.0 | Φ55×6.0 | Φ80×2.0 | Φ100×16 | Φ160×5.0 | |

| Φ10×0.5 | Φ20×2.2 | Φ30×2.5 | Φ40×8.0 | Φ55×7.0 | Φ80×2.2 | Φ100×18 | Φ160×5.5 | |

| Φ10×0.8 | Φ20×2.5 | Φ30×2.8 | Φ40×9.0 | Φ55×8.0 | Φ80×2.5 | Φ110×2.0 | Φ160×6.0 | |

| Φ10×1.0 | Φ20×2.8 | Φ30×3.0 | Φ40×10 | Φ55×9.0 | Φ80×2.8 | Φ110×2.2 | Φ160×7.0 | |

| Φ10×1.2 | Φ20×3.0 | Φ30×3.5 | Φ42×1.0 | Φ55×10 | Φ80×3.0 | Φ110×2.5 | Φ160×8.0 | |

| Φ10×1.5 | Φ20×3.5 | Φ30×4.0 | Φ42×1.2 | Φ55×12 | Φ80×3.5 | Φ110×2.8 | Φ160×9.0 | |

| Φ10×1.8 | Φ20×4.0 | Φ30×4.5 | Φ42×1.5 | Φ60×1.0 | Φ80×4.0 | Φ110×3.0 | Φ160×10 | |

| Φ10×2.0 | Φ20×4.5 | Φ30×5.0 | Φ42×1.8 | Φ60×1.2 | Φ80×4.5 | Φ110×3.5 | Φ160×12 | |

| Φ10×2.2 | Φ20×5.0 | Φ30×5.5 | Φ42×2.0 | Φ60×1.5 | Φ80×5.0 | Φ110×4.0 | Φ160×14 | |

| Φ10×2.5 | Φ20×5.5 | Φ30×6.0 | Φ42×2.2 | Φ60×1.8 | Φ80×5.5 | Φ110×4.5 | Φ160×16 | |

| Φ10×2.8 | Φ20×6.0 | Φ30×7.0 | Φ42×2.5 | Φ60×2.0 | Φ80×6.0 | Φ110×5.0 | Φ160×18 | |

| Φ10×3.0 | Φ20×7.0 | Φ30×8.0 | Φ42×2.8 | Φ60×2.2 | Φ80×7.0 | Φ110×5.5 | Φ160×20 | |

| Φ12×0.5 | Φ22×0.5 | Φ30×9.0 | Φ42×3.0 | Φ60×2.5 | Φ80×8.0 | Φ110×6.0 | Φ170×3.0 | |

| Φ12×0.8 | Φ22×0.8 | Φ30×10 | Φ42×3.5 | Φ60×2.8 | Φ80×9.0 | Φ110×7.0 | Φ170×3.5 | |

| Φ12×1.0 | Φ22×1.0 | Φ32×0.5 | Φ42×4.0 | Φ60×3.0 | Φ80×10 | Φ110×8.0 | Φ170×4.0 | |

| Φ12×1.2 | Φ22×1.2 | Φ32×0.8 | Φ42×4.5 | Φ60×3.5 | Φ80×12 | Φ110×9.0 | Φ170×4.5 | |

| Φ12×1.5 | Φ22×1.5 | Φ32×1.0 | Φ42×5.0 | Φ60×4.0 | Φ80×14 | Φ110×10 | Φ170×5.0 | |

| Φ12×1.8 | Φ22×1.8 | Φ32×1.2 | Φ42×5.5 | Φ60×4.5 | Φ80×16 | Φ110×12 | Φ170×5.5 | |

| Φ12×2.0 | Φ22×2.0 | Φ32×1.5 | Φ42×6.0 | Φ60×5.0 | Φ85×1.5 | Φ110×14 | Φ170×6.0 | |

| Φ12×2.2 | Φ22×2.2 | Φ32×1.8 | Φ42×7.0 | Φ60×5.5 | Φ85×1.8 | Φ110×16 | Φ170×7.0 | |

| Φ12×2.5 | Φ22×2.5 | Φ32×2.0 | Φ42×8.0 | Φ60×6.0 | Φ85×2.0 | Φ110×18 | Φ170×8.0 | |

| Φ12×2.8 | Φ22×2.8 | Φ32×2.2 | Φ42×9.0 | Φ60×7.0 | Φ85×2.2 | Φ120×2.0 | Φ170×9.0 | |

| Φ12×3.0 | Φ22×3.0 | Φ32×2.5 | Φ42×10 | Φ60×8.0 | Φ85×2.5 | Φ120×2.2 | Φ170×10 | |

| Φ12×3.5 | Φ22×3.5 | Φ32×2.8 | Φ45×1.0 | Φ60×9.0 | Φ85×2.8 | Φ120×2.5 | Φ170×12 | |

| Φ12×4.0 | Φ22×4.0 | Φ32×3.0 | Φ45×1.2 | Φ60×10 | Φ85×3.0 | Φ120×2.8 | Φ170×14 | |

| Φ14×0.5 | Φ22×4.5 | Φ32×3.5 | Φ45×1.5 | Φ60×12 | Φ85×3.5 | Φ120×3.0 | Φ170×16 | |

| Φ14×0.8 | Φ22×5.0 | Φ32×4.0 | Φ45×1.8 | Φ65×1.0 | Φ85×4.0 | Φ120×3.5 | Φ170×18 | |

| Φ14×1.0 | Φ22×5.5 | Φ32×4.5 | Φ45×2.0 | Φ65×1.2 | Φ85×4.5 | Φ120×4.0 | Φ170×20 | |

| Φ14×1.2 | Φ22×6.0 | Φ32×5.0 | Φ45×2.2 | Φ65×1.5 | Φ85×5.0 | Φ120×4.5 | Φ180×3.5 | |

| Φ14×1.5 | Φ22×7.0 | Φ32×5.5 | Φ45×2.5 | Φ65×1.8 | Φ85×5.5 | Φ120×5.0 | Φ180×4.0 | |

| Φ14×1.8 | Φ25×0.5 | Φ32×6.0 | Φ45×2.8 | Φ65×2.0 | Φ85×6.0 | Φ120×5.5 | Φ180×4.5 | |

| Φ14×2.0 | Φ25×0.8 | Φ32×7.0 | Φ45×3.0 | Φ65×2.2 | Φ85×7.0 | Φ120×6.0 | Φ180×5.0 | |

| Φ14×2.2 | Φ25×1.0 | Φ32×8.0 | Φ45×3.5 | Φ65×2.5 | Φ85×8.0 | Φ120×7.0 | Φ180×5.5 | |

| Φ14×2.5 | Φ25×1.2 | Φ32×9.0 | Φ45×4.0 | Φ65×2.8 | Φ85×9.0 | Φ120×8.0 | Φ180×6.0 | |

| Φ14×2.8 | Φ25×1.5 | Φ32×10 | Φ45×4.5 | Φ65×3.0 | Φ85×10 | Φ120×9.0 | Φ180×7.0 | |

| Φ14×3.0 | Φ25×1.8 | Φ35×0.5 | Φ45×5.0 | Φ65×3.5 | Φ85×12 | Φ120×10 | Φ180×8.0 | |

| Φ14×3.5 | Φ25×2.0 | Φ35×0.8 | Φ45×5.5 | Φ65×4.0 | Φ85×14 | Φ120×12 | Φ180×9.0 | |

| Φ14×4.0 | Φ25×2.2 | Φ35×1.0 | Φ45×6.0 | Φ65×4.5 | Φ85×16 | Φ120×14 | Φ180×10 | |

| Φ14×4.5 | Φ25×2.5 | Φ35×1.2 | Φ45×7.0 | Φ65×5.0 | Φ90×1.5 | Φ120×16 | Φ180×12 | |

| Φ15×0.5 | Φ25×2.8 | Φ35×1.5 | Φ45×8.0 | Φ65×5.5 | Φ90×1.8 | Φ120×18 | Φ180×14 | |

| Φ15×0.8 | Φ25×3.0 | Φ35×1.8 | Φ45×9.0 | Φ65×6.0 | Φ90×2.0 | Φ130×2.5 | Φ180×16 | |

| Φ15×1.0 | Φ25×3.5 | Φ35×2.0 | Φ45×10 | Φ65×7.0 | Φ90×2.2 | Φ130×2.8 | Φ180×18 | |

| Φ15×1.2 | Φ25×4.0 | Φ35×2.2 | Φ48×1.0 | Φ65×8.0 | Φ90×2.5 | Φ130×3.0 | Φ180×20 | |

| Φ15×1.5 | Φ25×4.5 | Φ35×2.5 | Φ48×1.2 | Φ65×9.0 | Φ90×2.8 | Φ130×3.5 | Φ190×3.5 | |

| Φ15×1.8 | Φ25×5.0 | Φ35×2.8 | Φ48×1.5 | Φ65×10 | Φ90×3.0 | Φ130×4.0 | Φ190×4.0 | |

| Φ15×2.0 | Φ25×5.5 | Φ35×3.0 | Φ48×1.8 | Φ65×12 | Φ90×3.5 | Φ130×4.5 | Φ190×4.5 | |

| Φ15×2.2 | Φ25×6.0 | Φ35×3.5 | Φ48×2.0 | Φ65×14 | Φ90×4.0 | Φ130×5.0 | Φ190×5.0 | |

| Φ15×2.5 | Φ25×7.0 | Φ35×4.0 | Φ48×2.2 | Φ70×1.0 | Φ90×4.5 | Φ130×5.5 | Φ190×5.5 | |

| Φ15×2.8 | Φ25×8.0 | Φ35×4.5 | Φ48×2.5 | Φ70×1.2 | Φ90×5.0 | Φ130×6.0 | Φ190×6.0 | |

| Φ15×3.0 | Φ26×0.5 | Φ35×5.0 | Φ48×2.8 | Φ70×1.5 | Φ90×5.5 | Φ130×7.0 | Φ190×7.0 | |

| Φ15×3.5 | Φ26×0.8 | Φ35×5.5 | Φ48×3.0 | Φ70×1.8 | Φ90×6.0 | Φ130×8.0 | Φ190×8.0 | |

| Φ15×4.0 | Φ26×1.0 | Φ34×6.0 | Φ48×3.5 | Φ70×2.0 | Φ90×7.0 | Φ130×9.0 | Φ190×9.0 | |

| Φ15×4.5 | Φ26×1.2 | Φ35×7.0 | Φ48×4.0 | Φ70×2.2 | Φ90×8.0 | Φ130×10 | Φ190×10 | |

| Φ15×5.0 | Φ26×1.5 | Φ35×8.0 | Φ48×4.5 | Φ70×2.5 | Φ90×9.0 | Φ130×12 | Φ190×12 |

Product Display

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for 100% Original China Cold Drawn Carbon Seamless Steel Pipe for Mechanical Processing API5l Line Pipe ERW Pipe, We often keep on with the principle of “Integrity, Efficiency, Innovation and Win-Win business”. Welcome to go to our website and never hesitate to communicate with us. Are you all set? ? ? Let us go!!!

100% Original China Welded Steel Pipes and Carbon Steel Pipe, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.